PERFORMANCE

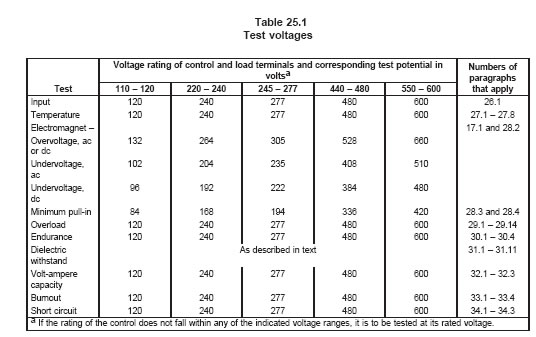

25 General

26 Input Test

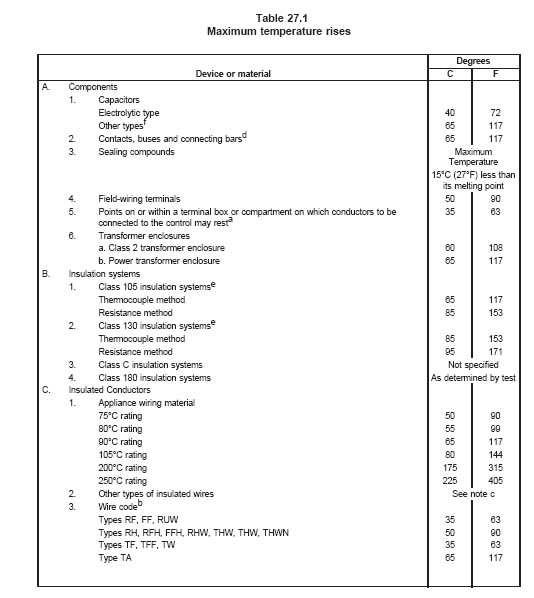

27 Temperature Test

28 Operation Test

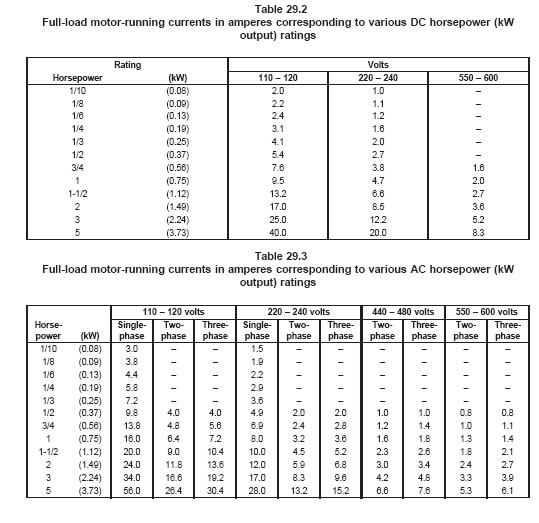

29 Overload Test

30 Endurance Test

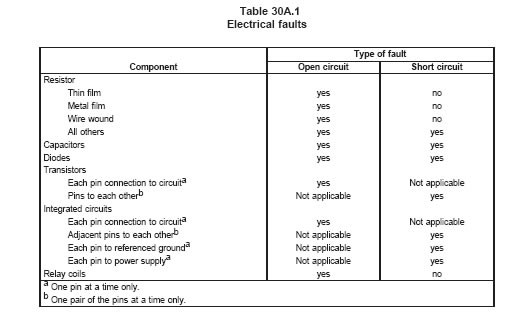

30A FMEA Procedures

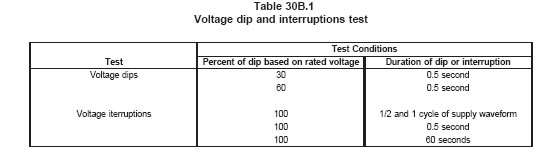

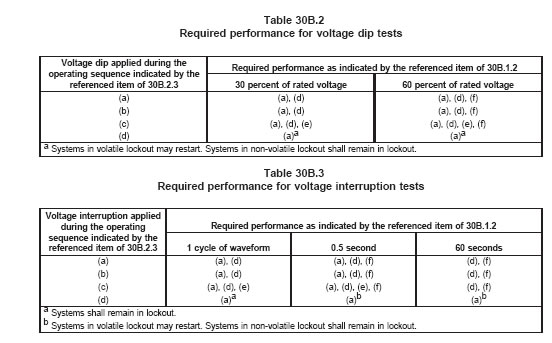

30B Mains Borne Perturbations, Magnetic and Electromagnetic Disturbances

30B.1 General

30B.2 Voltage dips and interruptions

30B.3 Ramp voltage tests

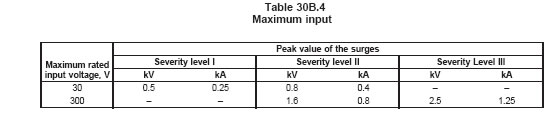

30B.4 Voltage/current surge tests

30B.5 Ring wave test

30B.6 Electrostatic discharge tests

30B.7 Radiated electromagnetic field test

30C Thermal cycling test for electronic devices

31 Dielectric Voltage-Withstand Test

32 Volt-Ampere Capacity Test .

33 Burnout Test

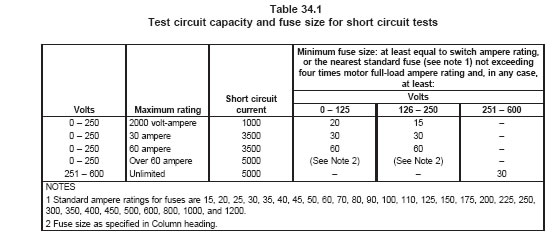

34 Short-Circuit Test

35 Tests on Leads and Push-In Terminals

35.1 Leads

35.2 Push-in terminals

36 Tests on Conduit Hubs and Nipples

37 Tests on Covers

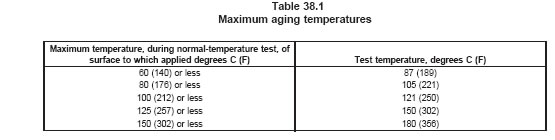

38 Marking Plate Adhesion Tests

38.1 General

38.2 Oven-aging test

38.3 Humidity test

38.4 Immersion test

38.5 Standard-atmosphere test

38.6 Unusual-condition exposure test

MANUFACTURING AND PRODUCTION TESTS

39 General

RATING

40 Details

MARKING

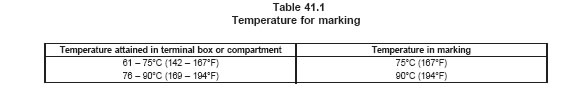

41 General Marking

42 Cautionary Marking

43 Visibility and Permanence

43.1 General

INSTRUCTIONS

44 Operating and Installation Instructions

SUPPLEMENT SA - SOFTWARE IN PROGRAMMABLE COMPONENTS

SA1 Application of Requirements

SA2 General

SA3 Qualification of Design, Implementation, and Verification Tools

SA4 Measures to Address Microelectronic Hardware Failure Modes

SA5 Documentation

SA6 Identification

APPENDIX A

1 Scope

1.1 These requirements cover primary safety controls for gas, gas-oil, and oil-fired appliances. These

safety controls are intended to sense the presence or absence of flame and, in the event of ignition failure

or unintentional flame extinguishment, cause safety shutdown.

1.2 These requirements are not intended to include those primary safety controls for gas appliances that

are of the type intended primarily for use with gas appliances having inputs of 400,000 Btu per hour (120

kW) or less per individual combustion chamber.

1.3 Requirements for the installation and use of primary safety controls are included in Standards of the

National Fire Protection Association, such as those for the installation of:

Oil-Burning Equipment, ANSI/NFPA 31-1987,

National Fuel Gas Code, NFPA 54, ANSI Z223.1-1988,

Ovens and Furnaces, ANSI/NFPA 86-1990, and

Furnace Explosions/Implosions in Multiple Burner Boiler-Furnaces, ANSI/NFPA 85C-1991.

1.4 Requirements for the installation of oil-burning equipment are included in codes such as:

The BOCA National Mechanical Code,

The Standard Mechanical Code, and

The Uniform Mechanical Code.

1.5 A product that contains features, characteristics, components, materials, or systems new or different

from those covered by the requirements in this standard, and that involves a risk of fire or of electric shock

or injury to persons shall be evaluated using appropriate additional component and end-product

requirements to maintain the level of safety as originally anticipated by the intent of this standard. A

product whose features, haracteristics, components, materials, or systems conflict with specific

requirements or provisions of this standard does not comply with this standard. Revision of requirements

shall be proposed and adopted in conformance with the methods employed for development, revision, and

implementation of this standard.

2 General

2.1 Except as indicated in 2.2, a component of a product covered by this standard shall comply with the

requirements for that component.

2.2 A component is not required to comply with a specific requirement that:

a) Involves a feature or characteristic not required in the application of the component in the

product covered by this standard, or

b) Is superseded by a requirement in this standard.

2.2 revised September 1, 2000

2.3 A component shall be used in accordance with its rating established for the intended conditions of use.

2.3 revised September 1, 2000

2.4 Specific components are incomplete in construction features or restricted in performance capabilities.

Such components are intended for use only under limited conditions, such as certain temperatures not

exceeding specified limits, and shall be used only under those specific conditions. Values stated without

parentheses are the requirement. Values in parentheses are explanatory or approximate information.

2.4 revised September 1, 2000

2.5 Any undated reference to a code or standard appearing in the requirements of this standard shall be

interpreted as referring to the latest edition of that code or standard.

3 Glossary名詞解釋

3.1 For the purpose of this standard, the following definitions apply.

3.2 3.2 revised and relocated as 3.10.1 February 17, 1995

3.3 COMBUSTION SAFEGUARD – See "Control, Primary Safety, 3.7."

3.4 CONTROL, INPUT (COMBUSTION) – A control that automatically regulates the firing rate at

predetermined air-fuel ratio in accordance with load demand. It may be a type that positions the air and

fuel supplies for low fire and high fire as required to meet the load demands, or it may be a modulating

type that gradually varies the air and fuel supplies within limits to meet the load demand.

3.5 CONTROL, LIMIT – An automatic safety control responsive to changes in liquid level, pressure, or

temperature and normally set beyond the operating range for limiting the operation of the controlled

equipment.

3.6 CONTROL, OPERATING – A control, other than a safety control or interlock, to start or regulate

appliance firing according to load demand and to stop or regulate output on satisfaction of demand or

upon reaching normal temperature or pressure in the appliance. Operating controls may also actuate

auxiliary equipment.

3.7 CONTROL, PRIMARY SAFETY 主要安全控制– An automatic control that monitors the operation of a gas-fired or

an oil-fired burner. It normally consists of the following sections that may be integrated into a common

Programming unit – A device that programs the burner through start-up and shutdown

operations in response to signals from regulating, limiting, and monitoring devices. It also

provides the timings, as required, in proper sequence, for purging, flame establishing periods,

and in case of flame failure, for safety shutdown (lockout).以自動方式監視瓦斯或油火器操控者,通常涵蓋下列部分,整合在一個程式物件內: 經該程式透過調整\限制\監視訊號而回應以[啟動]及[關閉]瓦斯器具

Combustion detector – A device that is responsive to flame properties. It monitors the flame at

the point of flame supervision and transmits a signal to the programming unit, indicating

absence or presence of flame.根據火焰物性,監視火焰並傳送訊號至程式單元呈現有無火焰狀態

An ignition source and/or an ignition device may be included as part of the primary safety control.

點火源及\或點火裝置可能是主要安全控制的一部分

3.7 revised February 17, 1995

3.8 CONTROL, SAFETY – An automatic control or interlock (including a relay, switch, or other auxiliary

equipment used in conjunction therewith to form a safety-control system) that is intended to reduce a

risk of fire, electric shock, or injury to persons.unit or may be separate units, interconnected by wiring:為以降低火災\電擊\人身傷害的自動控制或互鎖裝置(包括:結合使用relay, switch, or other auxiliary

equipment等,以形成一安全控式系統 )

3.9 ELECTRICAL CIRCUITS –

a) High-Voltage Circuit – A circuit involving a potential of not more than 600 volts and having

circuit characteristics in excess of those of a low-voltage or an isolated limited secondary circuit.

b) Low-Voltage Circuit – A circuit involving a potential of not more than 30 volts alternating

current (42.4 volts peak) or direct current and supplied by a primary battery or by a Class 2

transformer, or by a combination of transformer and fixed impedance, each of which, as a unit,

complies with the requirements for a Class 2 transformer. A circuit derived from a source of supply

classified as a high-voltage circuit, using resistance in series with the supply circuit as a means

of limiting the voltage and current, is not considered to be a low-voltage nor an isolated limited

secondary circuit.

c) Safety-Control Circuit – A circuit involving one or more safety controls.

d) Isolated Limited Secondary Circuit – A circuit of limited energy derived from an

isolated secondary winding of a transformer having a maximum capacity of 100

volt-amperes and

open-circuit secondary voltage not exceeding 1000 volts.

3.10 FLAME-FAILURE RESPONSE TIME – The interval between the occurrence of

flame

extinguishment and de-energizing the safety shutoff circuit.

3.10.1 FLAME DETECTOR – See Control, Primary Safety, 3.7.

3.2 revised and relocated as 3.10.1 February 17, 1995

3.11 IGNITION, CONTINUOUS – Ignition by an igniter is continuously maintained at ignition temperature

throughout the time the burner is in service, whether the main burner is firing or not.

3.12 IGNITION, INTERMITTENT – Ignition by an igniter that is automatically energized each time the

main burner is to be fired. Ignition is maintained during the entire period that the main burner is firing.

3.13 IGNITION, INTERRUPTED – Ignition by an igniter that is automatically energized each time the

main burner is to be fired. Ignition is maintained during the main burner flame-establishing period and then

automatically cut off.

3.14 IGNITION, MANUAL – Ignition by a device or source that is manually energized.

3.15 IGNITION, PROVED – Ignition by an igniter that is supervised by a primary safety control sensing

the presence of energy for ignition prior to permitting the main burner fuel to be delivered to the

combustion zone.

3.16 IGNITION, UNPROVED – Ignition by an igniter assumed to be energized during the main burner

flame-establishing period.

3.17 INTERLOCK – A control to prove the physical state of a required condition and to furnish the proof

to the primary safety-control circuit.

3.17.1 LOCKOUT

a) Volatile lockout – Denotes the safety shutdown condition of the control such that a restart can

be accomplished by either a manual reset at the control or by an interruption of the power supply

and its subsequent restoration.

b) Non-volatile lockout – Denotes the safety shutdown condition of the control such that a restart

can be accomplished only by a manual reset of the reset means at the control.

3.17.1 added January 2, 1998

3.18 MAIN BURNER FLAME-ESTABLISHING PERIOD – The interval of time the main burner fuel safety

shutoff valves are permitted to be open before the primary safety control is required to supervise the main

burner flame.

3.19 MANUAL RESET – The manual operation required after safety shutdown before the appliance can

be restarted.

3.20 PILOT – A flame, smaller than the main flame, that is utilized to ignite the fuel at the main burner or

burners.

3.21 PILOT, CONTINUOUS – A pilot that burns without turndown throughout the entire time the burner

assembly is in service, whether the main burner is firing or not.

3.22 PILOT, EXPANDING – A pilot that burns throughout the entire time the burner assembly is in

service, whether the main burner is firing or not. Upon a call for heat, the pilot is automatically expanded.

The pilot may be turned down automatically at the end of the main burner flame-establishing period.

3.23 PILOT, FLAME-ESTABLISHING PERIOD – The interval of time fuel is permitted to be delivered to

a proved pilot before the primary safety control is required to prove pilot flame.

3.24 PILOT, INTERMITTENT – A pilot that is lighted automatically each time there is a call for heat. It

burns during the entire period that the main burner is firing.

3.25 PILOT, INTERRUPTED – A pilot that is lighted automatically each time there is a call for heat. The

pilot fuel is cut off automatically at the end of the main burner flame-establishing period.

3.26 PILOT, PROVED – A pilot flame supervised by a primary safety control.

3.27 PURGE – To introduce air into the combustion chamber and the appliance flue passages in such

volume and manner as to replace the air or gas-air mixture contained therein.

3.28 RECYCLE – A characteristic in some programming primary safety controls for automatically lighted

burners that, upon accidental flame failure during a normal firing cycle and the subsequent shutoff of main

burner fuel, will provide, after a preestablished shutdown period and under a normal starting program, one

attempt to automatically light the main burner.

3.29 RELIGHT – A characteristic in some programming primary safety controls providing interrupted

ignition for automatically lighted burners that, upon accidental flame failure during a normal firing cycle,

will cause the ignition energy to be restored in not more than 0.8 seconds; then, if the main burner

flame is not reestablished, safety shutdown occurs.

3.30 REPEATABILITY – The ability of a control or interlock to maintain a constant set-point

characteristic.

3.31 SAFETY SHUTDOWN – Denotes the de-energization of the fuel flow means by the control such

that restart takes place only by a manual reset of the control or by automatic action of the control to

recycle.

3.31 revised January 2, 1998

3.32 SET POINT – A predetermined value to which a control or interlock is adjusted and at which it

performs its intended function.

3.33 SUPERVISE – To sense a condition requiring attention and initiate corrective action if necessary.

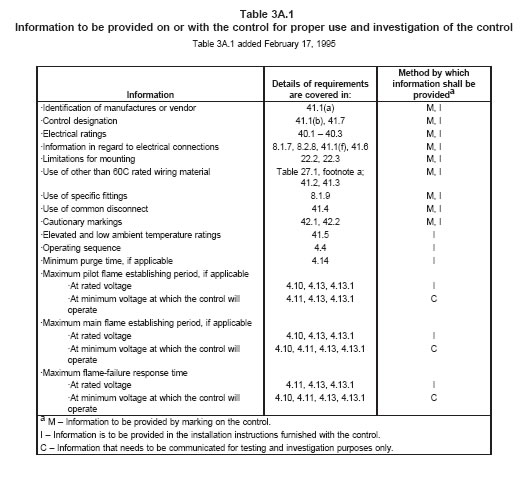

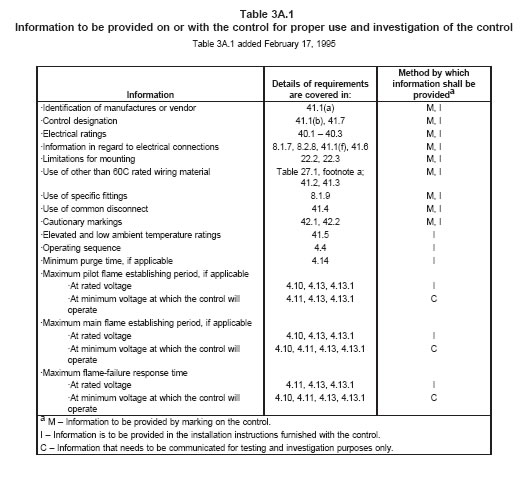

3A Instructions

3A added February 17, 1995

3A.1 Table 3A.1 summarizes the information that is to be provided on or with a control in the form of

marking, installation instructions or some form of communication for test and investigation purposes to

judge compliance with the requirements in this Standard.

CONSTRUCTION結構

4 General

4.1 The primary input circuit of a safety control shall be a two-wire, one-side-grounded system, having a

voltage rating of not more than a nominal 120 volts. A switch or protective device shall be in the circuit

electrically connected to the ungrounded supply conductor.

4.2 A safety programming circuit of a primary safety control:

a) Shall permit operation of the controlled equipment only when the circuit is closed, or

b) Shall be such that failure to close the circuit, or an accidental open circuit will cause the fuel

to be shut off within the prescribed flame-failure response time declared by the manufacturer or

prevent an attempt to start the burner.

4.2 revised February 17, 1995

Table 4.1

Primary safety-control timings in seconds

Table 4.1 deleted February 17, 1995

4.3 The control circuit shall be such that it will permit the connection of limit controls that can directly open

the circuits that function to interrupt the delivery of fuel for combustion.

4.4 The control circuit shall provide a safe-start component check so that either no

attempt to start the

burner will be made, the control remains in the prepurge state (if provided as part of the programming) or

the fuel will be shut off within the declared

maximum pilot or main flame establishing period whichever is

applicable, if the flame detection system, due to some fault, produces a signal indicating the presence of

flame.

For controls that incorporate electronic circuits, compliance is to be determined by

Section 30A,

FMEA Procedures. For controls not subject to FMEA Procedures, compliance

is to be determined by

simulating a flame prior to initiating the burner start-up and

then observing that either burner operations

does not occur or that safety shutdown

occurs without exceeding the declared pilot or main burner flame

establishing period.

4.4 revised February 17, 1995

4.5 With reference to 4.4, the faults to be considered are indicated in 30A.3.

4.5 revised February 17, 1995

4.6 A control shall not permit continued cycles of burner operation without providing

all the required safety

programming, including the provisions for purge if such is

declared as part of the control programming.

Faults of the circuit components shall not negate any part of the safety programming or alter the sequence

of operations. For

controls that incorporate electronic circuits, compliance is to be determined by

Section

30A, FMEA Procedures. For controls not subject to FMEA Procedures, compliance

is to be determined by

safe-start component check in accordance with 4.4 which shall

include a continuity check of the circuit to

establish that all circuit components are operational.

4.6 revised February 17, 1995

4.7 When the control interrupts the burner operation because of ignition, flame or control failure this shall

result in safety shutdown and volatile or non-volatile lockout.

See 3.17.1 and 3.31.Exception: If declared by the manufacturer the control may provide an attempt to restart the burner

through a recycle or relight operation. See 3.28 and 3.29, respectively.

4.7 revised January 2, 1998

4.8 A cover of a control shall be equipped with an interlock if opening or removal of the cover may cause

the system to falsely indicate the presence of flame that, in turn, may result in a risk of fire or injury to

persons.

4.9 Induction or capacity effects from extraneous sources, variations in field-installed control-circuit

wiring, or accidental grounding of circuits, including flame rods, shall

not cause a control to falsely indicate

flame when the control is installed in accordance with the manufacturer’s instructions. A special cable or

shield required for this purpose shall be furnished with each control.

4.10 A primary safety control shall provide at least the following operations, in proper sequence, for

programming the start-up and shut-down of the burner in accordance with the manufacturer’s declared

timings:

a) Pilot or main burner flame establishing period or both.

b) Safety shutdown within the flame-failure response time in the event of flame failure.

c) Volatile or non-volatile lockout.

4.10 revised February 17, 1995

4.11 For the operations indicated in 4.10 the manufacturer shall declare the timings at the rated voltage

and at the rated minimum and maximum ambient temperature ratings. For test purposes only, the timings

for these operations have to be declared also at the minimum voltage at which the control operates to

energize the fuel flow means.

4.11 revised February 17, 1995

4.12 revised and relocated as 25.5 February 17, 1995

4.13 The timings for pilot or main flame establishing period or both and for flame-failure response time

shall not exceed the declared maximum timings when tested at the rated

voltage and in the rated high

and low ambient temperature in accordance with 28.2.1 – 28.2.4. The timings shall be tested also at the

minimum voltage at which the control

operates to energize the fuel flow means and at 110 percent rated

voltage for both the

low and high ambient temperature ratings (see 4.13.1).

Exception: For controls for which the timings are provided by an electrically heated bimetal timer, the

timings under any combined conditions of low or high ambient temperature and increased or decreased

voltage shall not exceed the maximum declared timing by more than 300 percent.

4.13 revised February 17, 1995

4.13.1 With respect to 4.13, if the declared high ambient temperature rating is less than 66°C (150°F) the

timings are to be tested at 66°C instead of the rated high ambient temperature. Also, if the declared low

ambient temperature rating is higher than 0°C (32°F), the timings are to be tested at 0°C instead of the

rated low ambient temperature. The same tolerances that are specified in 4.13 apply to any combination

of the test ambient and voltage at which the control continues to operate.

4.13.1 added February 17, 1995

4.14 If provision for purge is provided as part of the control programming, the observed purge timings at

rated voltage and declared ambient shall not be less than declared timings. The minimum observed

timings under a combination of any voltage from 70 to 110 percent of rated voltage, with any ambient from

0 to 66°C (32 to 150°F), shall not be less than 80 percent of rated timings. If the control is rated for use

in ambients above or below those specified, the minimum observed timings shall not be less than 80

percent of declared timing at any combination of the declared high or low ambient and increased or

decreased test voltage.

4.14 revised February 17, 1995

4.15 In accordance with the definition in 3.10 the flame-failure response time is to be the interval between

the occurrence of flame extinguishment and the time all fuel shutoffs are de-energized, except that for

controls that use a thermally actuated combustion detector (see 4.17) the timing shall be the interval

measured from the time the sensing device first detects loss of flame to the time all fuel shutoffs are

de-energized.

4.15 revised February 17, 1995

4.16 4.16 deleted February 17, 1995

4.17 A thermally-actuated combustion-detector shall respond to a change in the temperature of flame or

flue gases (that is, respond to an increase or decrease in temperature rather than upon attaining a

predetermined temperature). Such a detector shall indicate flame outage in not more than 20 seconds

when tested in accordance with 28.5.

4.18 The safety programming of a primary safety control shall be such that the ignition system of an

automatically lighted burner will be activated only before or simultaneously with the delivery of fuel to the

ignition zone. If means for ignition are cut off before or at the termination of the pilot flame-establishing

period or after the main flame has been established, the ignition (pilot and any pilot or mainflame igniter)

shall remain off for the duration of that operating cycle.

Exception No. 1: For recycle type controls (see 3.28) the ignition means may be reenergized for an

attempt to restart the burner after in accordance with recycle procedures that are part of the control

programming.

Exception No. 2: For relight type controls (see 3.29) the ignition may be restored in not more than 0.8

seconds immediately following accidental extinguishment of the supervised flame.

4.18 revised February 17, 1995

4.19 Operating parts shall not sag, distort, melt, or oxidize during any of the tests specified herein.

4.20 An operating spring shall be retained and arranged to reduce abrasion, binding, buckling, or

interference with its free movement.

4.21 Unless the cover construction complies with the requirements for hinged covers in 5.2.3 and 5.2.6,

and unless all live parts are protected as required by 12.6, a handle, knob, or other operating means

provided for manual manipulation shall be arranged so that such manipulation may be done exterior to

the control enclosure. The position of such operating means shall be marked, if necessary, as a guide for

proper operation.

4.22 A device that involves manual operations that might be done only at the time of installation, during

servicing procedures, or seasonally, need not comply with 4.21 provided that the construction complies

with the requirements in 4.25, 4.26, 12.6, 12.11, 12.12, and 12.15.

4.23 Controls that are to be adjusted only at the time of installation, during servicing, or seasonally, shall

be judged with respect to the foregoing requirement.

4.24 Mechanical service functions that may have to be performed with the equipment energized include:

operation of valves or connection to fittings that may be necessary during charging or pneumatic-system

adjustment, adjusting water control, or expansion valves; adjusting the setting of temperature or pressure

controls with or without marked dial settings; resetting control trip mechanism; operating manual switches;

adjusting air-flow dampers. A factory-set and sealed control, having the set point sealed as described in

21.2 and 21.3 and not having marking or instructions for adjustment, is not considered to be adjustable.

4.25 An adjustable or resettable electrical control or manual switching device may be located or oriented

with respect to uninsulated live parts so that manipulation of the mechanism for adjustment, resetting, or

operation can be accomplished in the intended direction of access if uninsulated live parts are not located:

a) In front (in the direction of access) of the mechanism, and

b) Near any side or behind the mechanism, unless guarded.

4.26 Parts of a control that are subject to contact during normal operation, adjustments, and user

servicing shall be free of sharp corners and edges.

4.27 Relocated as 27.11 February 17, 1995

4A Safety Related Software

4A.1 Primary safety controls that employ microprocessors that include safety-related software shall be

evaluated using the Standard for Software in Programmable Components, UL 1998, as modified in

Supplement SA, Software in Programmable Components, of this standard.

4A.1 revised September 1, 2000利用微處理器等之安全相關控制軟體的主要安全控制,必須以UL1998軟體程式零件驗證之

4A.2 When applying the requirements in the Standard for Software in Programmable Components, UL

1998, the software Class shall be defined as Class 2.

4A.2 revised September 1, 2000

4A.3 A failure in the software during its intended operation shall not result in a loss of declared protective

function as specified by the manufacturer, and the following is to occur:

a) The overall control operates normally within the declared timings and sequence, or

b) The control operates to de-energize the fuel delivery circuit within the declared flame failure

response time and either establishes safety shutdown or fails to subsequently initiate a burner

startup, or completes the current burner operating cycle normally but will either fail to

subsequently start the burner or will establish safety shutdown.

Effective date for 4A.3 changed from January 2, 1998 to June 4, 1999

5 Frame and Enclosure本體與外殼

5.1 General

5.1.1 The mechanism of a control shall be protected by an enclosure to avoid damage to or interference

with operating parts.

Revised 5.1.1 effective February 25, 1996

5.1.2 An electron tube shall be enclosed or protected against damage. Such a tube, as well as a means

provided for manual manipulation, shall be located with respect to uninsulated live parts so that there will

be no likelihood of a person contacting such live parts during the normal changing of the tube or during

manual manipulation of parts intended for such purpose.

5.1.3 A piece, such as a dial or nameplate, that is in effect a part of the enclosure, shall be of metal or

other material as specified for the enclosure.

5.1.4 Cast metal for an enclosure shall be at least 1/8 inch (3.2 mm) thick at every point, of greater

thickness at reinforcing ribs and door edges, and not less than 1/4 inch (6.4 mm) thick at tapped holes for

conduit; except that, other than at plain or threaded conduit holes, die-cast metal shall not be less than

3/32 inch (2.4 mm) thick for an area greater than 24 square inches (155 cm2) or having any dimension

greater than 6 inches (152.4 mm), and shall not be less than 1/16 inch (1.6 mm) thick for an area of 24

square inches or less and having no dimensions greater than 6 inches. The area limitations for metal 1/16

inch thick may be obtained by the provision of reinforcing ribs subdividing a larger area. Die-cast metal of

0.035 inch (0.89 mm) minimum thickness may be employed in lieu of 1/16 inch thick die-cast metal if the

enclosure will not be used as a splice box and if the voltage rating of the complete control is such that the

potential between any two conductors does not exceed 250 volts ac or dc, and die-cast metal of 0.028

inch (0.71 mm) minimum thickness may be employed in lieu of 1/16 inch thick die-cast metal for an

enclosure housing only low-voltage circuits.

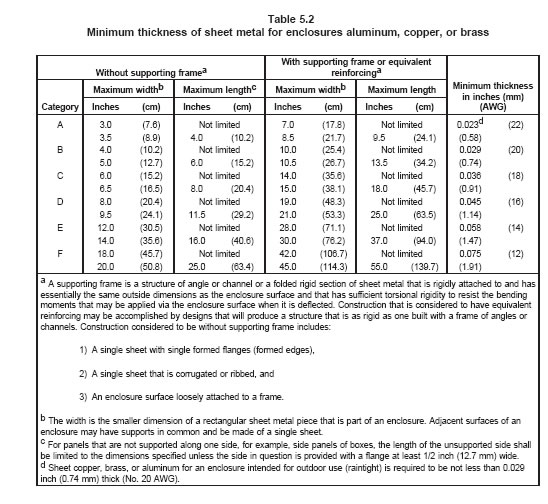

5.1.5 The thickness of a sheet-metal enclosure shall be as indicated in Tables 5.1 and 5.2, except that

steel shall not be less than 0.032 inch (0.81 mm) thick [0.034 inch (0.86 mm) if zinc-coated] and

nonferrous metal shall not be less than 0.45 inch (1.14 mm) thick at points where a wiring system is to be

connected.

5.1.6 A transformer shall be housed within its own enclosure or within the main enclosure of a control

within a combination thereof. A sheet-steel transformer enclosure shall have a thickness of not less than

0.026 inch (0.6 mm) if uncoated and not less than 0.029 inch (0.74 mm) if galvanized, except that sheet

steel having a thickness of not less than 0.020 inch (0.51 mm) if uncoated and not less than 0.023 inch

(0.85 mm) if galvanized may be used for a drawn end bell having maximum dimensions of 2-1/4 inches

(57.2 mm) on the flat portion and 1-1/2 inches (38.1 mm) at the base of the drawn portion. A cast-metal

transformer enclosure shall comply with the requirements in 5.1.4.

5.1.7 Glass covering an observation opening shall be secured in place so that it cannot be readily

displaced in service, and shall provide mechanical protection for the enclosed parts. Glass for an opening

not more than 4 inches (101.6 mm) in any dimension shall not be less than 1/16 inch (1.6 mm) thick. Glass

for a larger opening, but not more than 144 square inches (929 cm2) in area and having no dimension

greater than 12 inches (304.8 mm), shall not be less than 1/8 inch (3.2 mm) thick.

5.1.8 The mechanical strength of a:

a) Nonmetallic enclosure, and

b) Nonmetallic part (such as a reset knob, lever, or button) protruding through a hole in the

enclosure larger than the area of a 7/8 inch (22.2 mm) diameter circle

shall be at least equivalent to a sheet metal enclosure of the minimum thickness specified in Table 5.1.

5.1.8 separated into 5.1.8 and 5.1.8.1 February 17, 1995

5.1.8.1 A nonmetallic part protruding through a hole less than the area of a 7/8 inch (22.2 mm) diameter

circle shall be of noncombustible material.

5.1.8 separated into 5.1.8 and 5.1.8.1 February 17, 1995

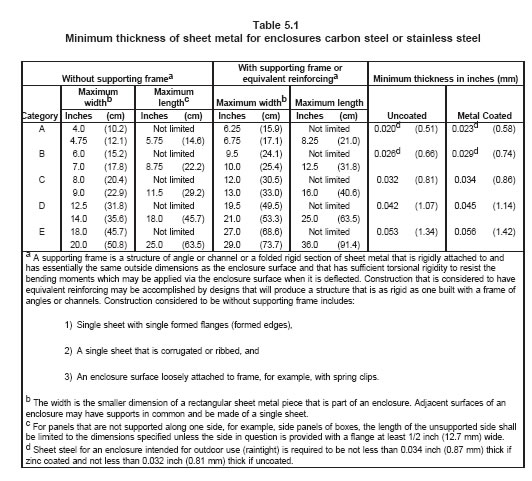

Table 5_1

5.1.9 Among the factors taken into consideration when judging the acceptability of a nonmetallic

enclosure or parts are:

a) The mechanical strength,

b) Resistance to impact,

c) Moisture-absorptive properties,

d) Combustibility and resistance to ignition from electrical sources,

e) Dielectric strength, insulation resistance, and resistance to arc tracking, and

f) Resistance to distortion and creeping at temperatures to which the material may be subjected

under conditions of normal or abnormal usage.

All these factors are considered with respect to aging.

5.1.10 If threads for the connection of conduit are tapped all the way through a hole in an enclosure wall,

or if an equivalent construction is used, there shall be no less than three threads in the metal, and the

construction of the control shall be such that a conduit bushing can be attached as intended.

5.1.10 revised and separated into 5.1.10 and 5.1.10.1 effective August 25, 1994

5.1.10.1 If threads for the connection of conduit are not tapped all the way through a hole in an enclosure

wall, conduit hub, or the like, there shall not be less than 3-1/2 threads in the metal and there shall be a

smooth, rounded inlet hole for the conductors that affords protection to the conductors equivalent to that

provided by a standard conduit bushing and that has an internal diameter approximately the same as that

of the corresponding trade size of rigid conduit.

5.1.10.1 revised and separated into 5.1.10 and 5.1.10.1 effective August 25, 1994

5.1.11 In an enclosure threaded for support by rigid conduit, at least five full threads shall be provided for

engaging the conduit.

Revised 5.1.11 effective August 25, 1994

5.2 Covers and doors

5.2.1 Doors or covers shall be provided with means for securing them to the enclosure.

5.2.2 Sheet metal screws threading directly into metal brackets or enclosure walls shall not be used for

attachment of covers or doors that have to be removed for installation or operation of the equipment. They

may thread into spring steel nuts permanently held in place and protected against corrosion. Machine

screws and self-tapping machine screws may thread directly into sheet-metal walls.

5.2.3 An enclosure cover shall be hinged if it gives access to a fuse, thermal cutout, or any protective

device, the normal functioning of which requires renewal or resetting, or if it is necessary to open the cover

in connection with the normal operation of the control.

5.2.4 A door or cover that provides access to a fuse or thermal cutout in other than a low-voltage circuit

shall shut against a 1/4 inch (6.4 mm) rabbet, or the equivalent, or shall have either turned flanges for the

full length of four edges or angle strips fastened to it. Flanges or angle strips shall fit closely with the

outside of the walls of the box and shall overlap the edges of the box not less than 1/2 inch (12.7 mm).

A construction that affords equivalent protection or a combination of flange and rabbet is acceptable.

5.2.5 Strips used to provide rabbets or angle strips fastened to the edges of a door shall be secured at

not less than two points, not more than 1-1/2 inches (38.1 mm) from each end of each strip and at points

between these end fastenings not more than 6 inches (152.4 mm) apart.

5.2.6 A hinged cover shall not depend solely upon screws or other similar means requiring the use of a

tool to hold it closed but shall be provided with a catch or spring latch; except that if a hinged cover is

provided, although not required, a hasp, sliding latch, or other means for holding the cover closed may be

employed.

5.2.7 No wires other than those leading to a part mounted on the door or cover or those of a low-voltage

nonsafety circuit shall be brought out through the door or cover of an enclosure.

5.2.8 If low-voltage nonsafety wiring is brought out through the door or cover, the construction shall

comply with the requirements in 8.1.10 and 20.1.3. The construction shall be such that the wires are not

subject to strain or mechanical damage when the door is opened or the cover is removed.

5.3 Openings

5.3.1 5.3.1 revised and relocated as 5.3.2.1 effective February 25, 1996

5.3.1.1 An opening shall not be provided in an enclosure that houses a fuse or any portion of a circuit

breaker other than the operating handle, unless the construction affords containment of electrical fault

disturbances equivalent to that provided by an enclosure complying with the requirements in 5.15 – 5.17.

Added 5.3.1.1 effective February 25, 1996

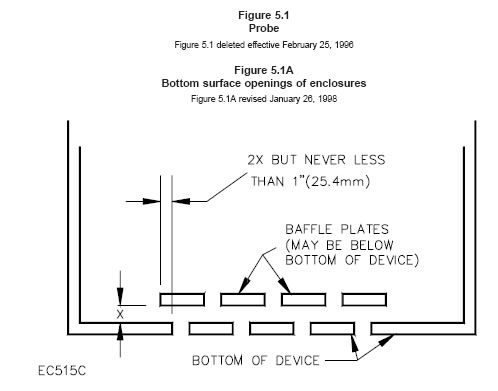

5.3.2 The following requirements apply to openings:

a) An opening shall not be provided in a compartment or part of an enclosure that contains

field-wiring splices in a line-voltage circuit.

b) No openings shall be located in the mounting surface of an enclosure.

Exception: The following openings may be located in the mounting surface of an enclosure:

1) A mounting opening.

2) A maximum of four openings provided for the escape of air or paint during a painting

process. The maximum dimension of such an opening shall not exceed 1/8 inch (3.2 mm).

3) A maximum of four unused holes provided for mounting of internal components. The

maximum dimension of such an opening shall not exceed 3/16 inch (4.8 mm).

c) If the bottom surface is not the mounting surface, an opening may be provided in the bottom

surface of an enclosure if the opening does not permit materials to fall directly out from the interior

of the unit. See Figure 5.1A for an example of an acceptable construction.

d) The shortest distance between an opening and the bottom of an enclosure or a

wall-mounting

surface shall be at least one-quarter of the enclosure height or depth, respectively, or 1 inch (25.4

mm), whichever is less.

e) There shall be no emission of flame or molten material, or manifestation of risk of fire, during

normal or abnormal tests on the control, such as transformer burnout and burnout of a relay with

blocked armature.

f) Unless the construction of a device provided with forced ventilation is such that there is no

direct path between live parts and the outlet opening, burnout tests in addition to those mentioned

in (d) shall be conducted to determine that there is no emission of flame or molten material

through the opening.

g) Air from an opening, either forced or otherwise, shall not be directed:

1) Into a duct or into a concealed space in a building,

2) Against the mounting surface, and

3) So that a disturbance would be propagated to other equipment if such

propagation

would cause a hazardous condition to exist.

h) No more than four holes for mounting an enclosure having a maximum dimension

of 18 inches

(457 mm); six holes for an enclosure with a maximum dimension of

more than 18 inches, but less

than 48 inches (1.2 m); eight holes for an

enclosure with a maximum dimension of 48 inches or

more. Four of the holes

for mounting an enclosure with a maximum dimension of 12 inches (305

mm) may

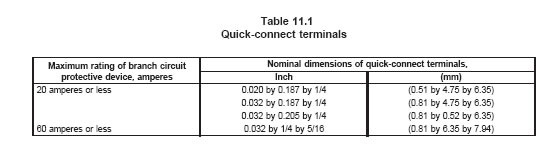

be keyhole slots having the configuration illustrated in Figure 5.3. The dimensions

shown in Figure 5.3 may vary if the area sequivalent. Four of the holes for mounting

a larger

enclosure may be keyhole slots, the dimensions of which are not specified,

and which shall be

judged with regard to the enclosure dimensions and configuration.

Revised 5.3.2 effective February 25, 1996

5.3.2.1 The smaller dimension (width) of an opening in an enclosure around a dial,

adjusting knob, lever,

handle, pointer, or the like shall be no more than 1/8 inch

(3.2 mm) for any setting or position of the dial,

knob, and the like.

5.3.1 revised and relocated as 5.3.2.1 effective February 25, 1996

figure5_1

6 Corrosion Protection銹蝕保護

6.1 Iron and steel parts, except bearings, thermal elements, laminated relay cores,

and the like, where

such protection is impracticable, shall be protected against

corrosion by enameling, galvanizing,

sherardizing, plating, or other equivalent means.

6.2 The requirement in 6.1 applies to enclosing cases whether of sheet steel or cast

iron, and to other

parts upon which proper mechanical operation may depend. It does

not apply to a part of iron or steel that

is not current-carrying, if the failure of

such an unprotected part would not be liable to result in a risk of

fire. A part made

of stainless steel does not require additional protection against corrosion.

7 Insulating Material絕緣材料

7.1 Material for the mounting of live parts shall be porcelain陶瓷, phenolic composition電木,cold-molded

composition, or material having equivalent properties relating to mechanical and electrical strength;

resistance to burning, moisture,arcing, and creep (flow due to stress); thermal endurance and resistance

to temperatures encountered in use.

7.2 Vulcanized fiber may be used for insulating bushings, washers, separators, and

barriers but not as

the sole support for uninsulated current-carrying parts other

than a low-voltage circuit.

8 Wiring Connections電路接線

8.1 General

8.1.1 Wiring connections are considered to be those that are made to the control

when the control is

installed.

8.1.2 A control shall be provided with wiring terminals or leads for the connection of conductors of at least

the size required by the National Electrical Code, ANSI/NFPA 70-1993, corresponding to the rating of the

control.

8.1.3 A terminal box or wiring compartment shall be located so that wire connections therein will be

accessible for inspection, without disturbing either high-voltage or safety-circuit wiring, after the control is

installed in the intended manner, except that for an outlet box mounted control, wire connections may be

accessible upon removal of the control from the outlet box.

8.1.4 A lead shall be wire having insulation equivalent to 0.028 inch (0.71 mm) thick thermoplastic

insulation rated at least 60°C, 600 V. Such a lead shall not be smaller than No. 18 AWG (0.82 mm2) and

shall have a free length of at least 6 inches (152.4 mm).

Exception: The lead may be less than 6 inches long if it is evident that the use of a longer lead might

result in a risk of fire or electric shock.

8.1.5 Leads for field connections (使用者會去接)shall be provided with strain relief so that mechanical stress is not

transmitted to terminals, splices or interior wiring.

8.1.6 The surface of an insulated lead intended solely for the connection of an equipment-grounding

conductor shall be green with or without one or more yellow stripes. No other conductor visible to the

installer shall be so identified.

8.2.6 A quick-connect terminal shall be provided with means to be mechanically interlocked to the mating

terminal and the mating terminal shall be shipped with the control together with instructions for their

installation.

8.2.7 Except for a low-voltage nonsafety circuit, a terminal shall be constructed so that the conductor will

make metal-to-metal contact with the terminal plate as well as with any wire binding screw when the

conductor is secured to the terminal.

8.2.8 A terminal intended for connection of a grounded supply conductor shall be of

or

plated with metal

that is substantially white in color and shall be readily distinguishable from other terminals, or identification

of that terminal shall

be shown in some other manner, such as on an attached wiring diagram. A lead

intended

for connection of a grounded supply conductor shall be finished to show a white or

natural grey

color and shall be distinguishable from the other leads.

8.2.9 A terminal solely for connection of an equipment-grounding conductor shall secure a conductor of

the size acceptable for the particular application, in accordance with the National Electrical Code,

ANSI/NFPA 70-1993.

8.2.10 A wire-binding screw intended for the connection of an equipment-grounding conductor shall have

a slotted, or hexagonal green-colored head. A pressure-wire connector intended for connection of such a

conductor shall be identified by being marked "G," "GR," "GROUND," "GROUNDING," or by a marking

on a wiring diagram provided on the control. The wire-binding screw or pressure-wire connector shall be

located so that it is unlikely to be removed during intended servicing of the control.

8.2.11 If a control includes a lampholder of the Edison screw-shell type, the identified grounded terminal

or lead shall be electrically connected to the screw shell of the lampholder.

8.3 Wiring space線路空間

8.3.1 Space shall be provided within the enclosure of a control to allow room for the distribution and

stowing of wires and cables required for the wiring of the control.

See also 23.4.

9 Current-Carrying Parts帶電體

9.1 Current-carrying parts shall be silver, copper, copper alloys, or other metal

acceptable for such use.

9.2 Uninsulated live parts, including terminals and contact assemblies, shall be secured

to their

supporting surfaces by methods other than friction between surfaces so that they will be prevented from

turning or shifting in position.

9.3 A lock washer is acceptable to prevent turning of a terminal or connection stud.

10 Internal Wiring內部線路

10.1 The internal wiring of a control shall consist of wires of a type that is acceptable

for the temperature

and voltage to which it is to be subjected.

10.2 Except as indicated in 10.4 and 10.5, the internal wiring of a control shall consist of insulated

conductors having a voltage rating and current-carrying capacity for their intended load. Insulated

conductors for a high-voltage circuit shall be wire having insulation equivalent to 0.028 inch (0.71 mm)

thick thermoplastic insulation rated at least 60°C, 600 V. Insulated conductors for a low-voltage

safety-control and isolated limited secondary circuit shall be Type RFH-1 or TF or wiring having insulation

equivalent in electrical and mechanical properties to that of Type RFH-1 or TF wire. See also 20.1.1.

10.3 These requirements are not intended to exclude the use of printed wiring material.

10.4 If the use of a short length of insulated conductor (for example, a short coil,

lead, or the like) is not

feasible, noncarbonized beads or electrical insulating tubing

may be employed. Tubing shall not be

subjected to sharp bends, tension, compression, or repeated flexing, and shall not contact sharp edges,

projections, or corners. The wall thickness at any point for the smallest sizes of polyvinyl chloride tubing

shall not be

less than 0.017 inch (0.43 mm). For insulating tubing of other types, the thickness

shall not

be less than that providing mechanical strength, dielectric properties, heat

and moisture-resistant

characteristics, and the like, at least equal to those of 0.017

inch thick polyvinyl chloride tubing.

10.5 An insulated conductor may be employed within an enclosed control for a short wire length if it is

impractical to insulate such a conductor.

10.6 An uninsulated conductor or a conductor utilizing tubing or noncarbonizable beads for insulation

shall not be employed outside of an enclosed control. An uninsulated conductor shall be supported so that

the required spacings will be maintained.

10.7 A wireway shall be smooth and free from sharp edges, burrs, fins, moving parts,

and the like, that

may cause abrasion of the insulation on conductors. Mounting screws shall not project more than 3/16

inch (4.8 mm) into a wireway and shall have flat or blunt ends.

10.8 Holes in sheet-metal walls through which insulated wires pass and on which they may bear shall be

provided with smoothly rounded bushings or shall have smooth, rounded surfaces so that there is no

abrasion of the insulation.

10.9 Joints and connections shall be mechanically secure and shall provide reliable electrical contact

without strain on connections and terminals. Except as indicated

in 10.10, soldered connections shall be

mechanically secure before being soldered.

10.10 Connections made to printed wiring boards need not be made mechanically secure

provided the

soldering is done by a machine in a process in which the soldering time and solder temperature are

automatically controlled.

10.11 A joint shall be provided with insulation equivalent to that required for the wires involved if

permanence of spacing between the joint and uninsulated live parts of opposite polarity or grounded dead

metal parts is not maintained.

11 Grounding接地

11.1 A control, except one intended for use only in a low-voltage circuit, shall have provision for

grounding all dead metal parts that are exposed or that are likely to be touched by a person during

intended operation or adjustment of the control, and that are likely to become energized.

11.2 All exposed dead metal parts requiring grounding shall be electrically connected

to an equipment

grounding terminal or lead.

11.3 To determine if a part is likely to become energized, it shall be evaluated on the

basis of factors such

as proximity to wiring and live parts, thickness and type of insulation, and by tests that may include

burnout and dielectric withstand after overload, endurance, conditioning, or aging. Guards, baffles, and

internal covers that do not require tools for removal will be removed when determining whether a part is

exposed to contact.

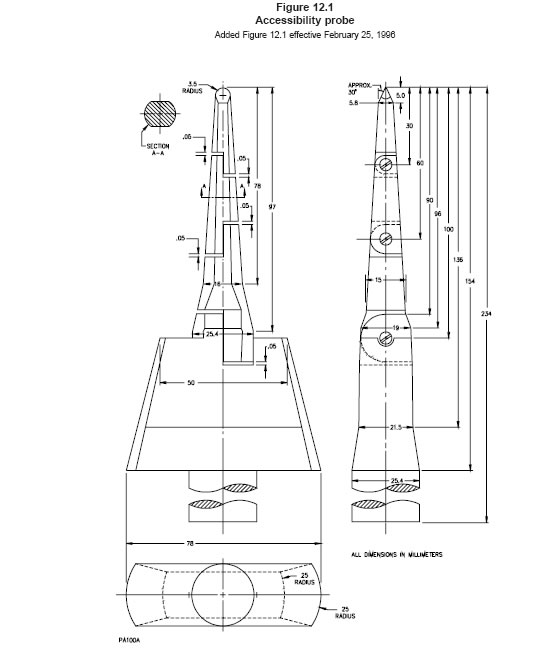

A part that can be contacted by a 3/4 inch (19.1 mm) diameter rod of any length or

by the probe illustrated in Figure 12.1, when inserted through openings in permanently attached guards

or baffles, is considered exposed for the purposes of grounding.

Revised 11.3 effective February 25, 1996

11.4 A metal part as described below need not to be grounded:

a) An adhesive-attached metal-foil marking, screw, handle, or the like, that is located

on the

outside of enclosure or cabinet and isolated from electrical components or wiring

by grounded

metal parts.

b) An isolated metal part, such as a magnet frame or armature,

small assembly screw,

or the like,

that is separated from wiring

and uninsulated live parts.

c) A panel or cover that does not enclose uninsulated live parts if insulated parts and wiring are

separated from the panel or cover.

d) A panel or cover that is insulated from electrical components and wiring by an

attached

insulating barrier of vulcanized fiber, varnished cloth, phenolic composition,

or similar material not

less than 1/32 inch (0.8 mm) thick.

e) A part on the back side of a component mounting panel or a part located so as to

require major

disassembly by using tools, unless it is likely that servicing will be done while energized after the

disassembly has been made.

11.5 Except as indicated in 11.4, uninsulated metal parts of cabinets, electrical

enclosures, motor frames

and mounting brackets, controller mounting brackets, capacitors

and other electrical components,

interconnecting tubing and piping, and the like shall be bonded for grounding if they may be contacted by

the user or service personnel.

11.6 A soldering lug, a push-in (screwless) connector, or a quick-connect or similar friction-fit connector

shall not be used for a field-connected grounding terminal.

11.7 An internal connection for bonding internal parts to the enclosure for grounding

(but not for a

field-installed grounding conductor) may employ a quick-connect terminal, provided the connector is not

liable to be displaced. The terminal shall be limited for

use with a branch circuit protective device rated 60

amperes or less and the size of the quick-connect terminal shall be as specified in Table 11.1.

11.8 The equipment-grounding terminal or lead grounding point shall be connected to the

frame or

enclosure by a positive means, such as by a bolted or screwed connection. The grounding connection

shall penetrate nonconductive coatings, such as paint or vitreous enamel. The grounding point shall be

located so that it is unlikely that the grounding

means will be removed during normal servicing.

11.9 Except as indicated in 11.10, the circuitry of a control shall be arranged so that

the

equipment-grounding connection or conductor, the enclosure, the frame, the component-mounting panel,

and the earth ground do not carry current except in the instance of an electrical fault.

11.10 A single-point reference ground may be employed in a low-voltage or isolated limited secondary

circuit. The enclosure, frame, or panel, including bolted joints may carry the current of a low-voltage

circuit. In neither of these instances is such current to be

carried through the field-equipment grounding

means, the metallic raceway or other power-supply grounding means, or the earth ground.

11.11 A grounded-circuit conductor shall not be grounded at or in conjunction with a control.

11.12 Live parts and wiring shall be maintained away from unbonded parts, such as relay and contactor

magnets and armatures by clamping, routing, or equivalent means.

11.13 If a component such as a remote sensor is likely to be separated from its normal grounding means

after installation in the end-use appliance for purposes of testing or adjustment while the equipment is

energized, it shall be provided with a bonding terminal

or a bonding conductor that does not require

removal for such service.

11.14 A bonding conductor shall be of copper, a copper alloy, or other material acceptable for use as an

electrical conductor. Ferrous metal parts in the grounding path shall be protected against corrosion by

enameling, galvanizing, plating, or equivalent means. A separate bonding conductor or strap shall:

a) Be protected from mechanical damage or be located within the confines of the outer enclosure

or frame, and

b) Not be secured by a removable fastener used for any purpose other than bonding unless the

bonding conductor is unlikely to be omitted after removal and replacement of the fastener.

11.15 Bonding shall be by a positive means, such as by clamping, riveting, bolted or screwed connection,

or welded or soldered connections using materials having a melting point greater than 850°F (455°C) or

by an equivalent construction complying with the requirements in 11.20. A bonding connection shall

penetrate nonconductive coatings, such as paint or vitreous enamel. Bonding around a resilient mount

shall not depend on the clamping action of rubber

or similar material.

11.16 The continuity of a grounding system shall not rely on the dimensional integrity of nonmetallic

material.

11.17 A single machine screw that is used for bonding purposes through screw threads shall engage at

least two full threads in the metal. Two sheet metal or machine screws shall be considered an equivalent

construction.

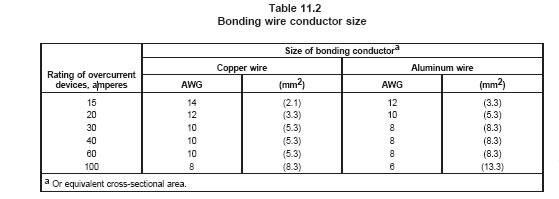

11.18 Unless tested as specified in 11.20, the size of a conductor or strap used for bonding a motor frame or component shall be as specified in Table 11.2 or shall be the same as that of the conductor supplying the motor or component, whichever is smaller.

table11.2

11.19 If more than one size branch circuit overcurrent device is involved, the size of the bonding

conductor shall be based on the rating of the overcurrent device intended to provide ground-fault

protection for the component bonded by the conductor. For example, if a motor is individually protected

by a branch circuit overcurrent device smaller than other overcurrent devices used with the equipment,

the size of a bonding conductor for that motor shall be based on the overcurrent device intended for

ground-fault protection of the motor.

11.20 The adequacy of a bonding connection or conductor that does not comply with the requirements in

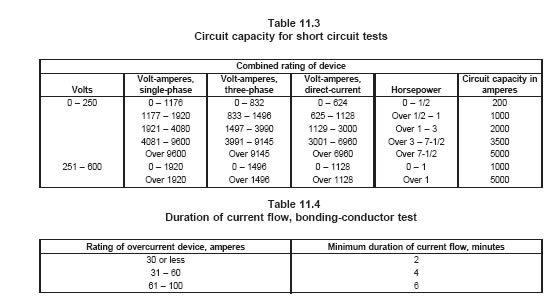

11.15 and 11.18 shall be established by subjecting the connection to the following tests:

a) The connection or conductor shall not open under an overload test of twice the branchcircuit

overcurrent device rating, but not less than 40 amperes, maintained for the interval

specified in Table 11.4.

b) Three samples of the connection or conductor shall not open under a limited short-circuit

test of a current specified in Table 11.3 in series with a fuse of the rating of the branch circuit

overcurrent device to which the equipment will be connected. The test circuit is to have a power

factor of 0.9 – 1.0 and is to be limited to the current specified, at the voltage stated in Table

25.1. The open-circuit voltage of the test circuit is to be not less than 100 percent nor more

than 105 percent of the specified voltage. The circuit is to be connected through a

nonrenewable fuse, the characteristics of which are such that the fuse will not open in less than

12 seconds when carrying twice the fuse rating current.

table 11.3 table 11.4

11.21 The resistance between the point of connection of the equipment grounding means,

at or within the

device, and any

other point in the grounding circuit shall be not more

than 0.1 ohm.

11.22 Compliance with the requirements of 11.21 may be determined by a Wheatstone Bridge, except

that if unacceptable results are recorded, an alternating current of at least 20 amperes from a power

supply of not more than 12 volts is to be passed from the point of connection of the equipment grounding

means to the metal part in the grounding circuit, and the resulting drop in potential is to be measured

between the two points. The resistance in ohms is to be determined by dividing the drop in potential in

volts by the current in amperes passing between the two points. The grounding conductor of a

power-supply cord is not to be included in this measurement.

12 Accessibility帶電體保護

12.1 These requirements apply to live parts in other than low-voltage circuits.

12.2 Live parts shall be located and enclosures and covers arranged so that persons are not likely to be

exposed to a risk of electric shock while removing or replacing a cover. This requirement is also applicable

to controls that are mounted on or form a cover for a junction box or wiring enclosure.

12.3 Electrical parts of controls shall be located or enclosed to reduce the risk of unintentional contact

with an uninsulated live part. Additionally, electrical parts shall be located or enclosed so that protection

against unintentional contact or shorting of live parts that could result in a malfunction of the controlled

equipment is provided. For the purpose of these requirements, film-coated wire is considered to be an

uninsulated live part.

Exception: An enclosure is not required for a device intended for assembly as part of another device.

Revised 12.3 effective February 25, 1996

12.4 An opening in an enclosure of a control is acceptable if an accessibility probe as illustrated in Figure

12.1, when inserted into the opening, cannot be made to touch any

part that involves the risk of electric

shock to the end-user or service personnel. However, in no case shall the opening be large enough to

permit the entrance of a 1 inch (25.4 mm) diameter rod.

Added 12.4 effective February 25, 1996

12.5 The accessibility probe shall be articulated into any configuration and shall be rotated or angled to

any position before, during, or after insertion into the opening, and the penetration shall be to any depth

allowed by the opening size, including minimal depth combined with maximum articulation.

Added 12.5 effective February 25, 1996

figure12.1

12.6 If any part of the enclosure must be opened or removed as part of normal operation, regular

adjustment, or regular or required maintenance (set point adjustment, timer or time of day clock

adjustment, battery replacement, and the like) with or without the use of tools, or can be opened or

removed without the use of tools, the accessibility probe is to be applied without the part in place.

Revised 12.6 effective February 25, 1996

12.7 A live heat sink for a solid state component, a live relay-frame, and the like, shall comply with the

requirements in 12.6, 12.11, and 12.13, but regardless of its location, shall either be guarded to prevent

contact by persons, or the equipment shall be marked in accordance with 42.2, except as indicated in

12.10.

12.8 With respect to 12.7, it is to be noted that the size, shape, material, and color give

a heat sink or

relay-frame the appearance of a dead metal part. Other types of live parts that can be mistaken for dead

shall be judged similarly.

12.9 A guard, baffle, and internal cover that do not require tools for removal shall be removed when

determining whether a part is exposed to contact by the user. A part that can

be contacted by a 3/4 inch

(19.1 mm) diameter rod of any length or by the probes shown in Figures 12.1, when inserted through

openings in a permanently attached guard or baffle is considered exposed for the purposes of protecting

persons.

12.10 A part on the back side of a component mounting panel or a part located so as to require major

disassembly by using tools is not considered to be exposed to the user, and such a part is not considered

exposed to service personnel unless it is likely that servicing will be done while energized after the

disassembly has been made.

12.11 An uninsulated live part or a moving part shall be located, guarded, or enclosed so

as to reduce

the likelihood of accidental contact by service personnel adjusting or resetting controls,

or performing

mechanical service functions that may have to be performed with the equipment energized.

12.12 In determining compliance with the requirements in 4.25, uninsulated live parts in a

30 volts or less

limited-energy circuit in accordance with 3.9(b) and (d) are not to be considered.

12.13 An electrical component that may require examination, adjustment, servicing, or maintenance while

energized shall be located and mounted with respect to other components

and with respect to grounded

metal parts so that it is accessible for electrical service functions without subjecting service personnel to

the risk of electric shock or injury to persons from adjacent moving parts. Access to the components in

the control assembly shall not be impeded in the direction of access by other components or by wiring.

12.14 A live part that is recessed at least 1/8 inch (3.2 mm) from any point of contact during the process

of removal and replacement of a cover is considered as not presenting a risk of electric shock if it is

demonstrated by trial removal and replacement of the cover that the live part cannot be contacted during

the removal and replacement process. A projection or guard may be incorporated for the purpose of

providing the equivalent of the 1/8 inch recess.

12.15 Accessibility and protection from the risk of electric shock and injury to persons may be obtained

by mounting the control components in an assembly so that unimpeded access is provided to each

component through an access cover or panel in the outer cabinet (if provided) and the cover of the control

assembly enclosure.

12.16 The electrical components referred to in the preceding paragraphs include the following: fuses,

adjustable or resettable overload relays, manual or magnetic motor controllers, magnetically operated

relays, adjustable or resettable pressure or temperature controls, manual switching devices, clock timers,

and incremental voltage tap and motor-speed tap terminals for variable speed motors. Such components

in a limited energy circuit of 30 volts or less in accordance with 3.9(b) or (d) shall comply with the

requirements in 12.13 in their relation to uninsulated live parts in a circuit of greater energy level and to

moving parts.

12.17 Totally enclosed current or potential type start relays for single-phase motors are

not considered

as requiring the accessibility stated in the foregoing paragraphs.

12.18 The following are not considered to be uninsulated live parts: coils of controllers, relays and

solenoids, and transformer windings, if the coils and windings are provided with acceptable insulating

overwraps at least 0.028 inch (0.71 mm) thick or equivalent (see 18.2.9), enclosed motor windings,

terminals and splices with acceptable insulation, and insulated wire.

13 Transformers變壓器

13.1 A transformer intended to furnish power to a low-voltage circuit shall be of the isolated-secondary

type.

14 Capacitors電容器

14.1 A capacitor shall employ such materials and shall be constructed so that it will not constitute a risk

of fire. It shall not be adversely affected by the temperatures attained by the device under the most severe

conditions of normal use. A paper capacitor shall be impregnated or enclosed to exclude moisture. An

electrolytic or other type of capacitor and a capacitor intended for connection directly across the line shall

be investigated under conditions of actual service to determine if it is acceptable for the applications.

15 Fuseholders保險司座

15.1 A fuseholder shall be of either the cartridge enclosed or plug fuse type. A plug fuse shall be limited

to use with equipment rated at not more than 125 or 125/250 volts.

16 Mercury-Tube Switches水銀管開關

16.1 A mercury tube switch shall be housed in an enclosure. Wire leads shall be as short as possible and

shall terminate at eyelets or the equivalent, or in soldered connections at terminal plates on the supporting

base, or shall be fastened so that no strain will be put upon the mechanism. See also 31.8.

17 Coil Windings 漆包線

17.1 Coil windings of a motor, a relay, a transformer, and the like, shall resist the absorption of moisture.

18 Spacings間隙

18.1 General

18.1.1 Live screwheads or nuts on the underside of a base shall be countersunk not less than 1/8 inch

(3.2 mm) in the clear, and then covered with a waterproof, insulating, sealing compound that will not melt

at a temperature 15°C (27°F) higher than the normal temperature the material will attain in service, and

not less than 65°C (149°F) in any case; except that if such parts are staked, upset, or otherwise prevented

from loosening, they need not be recessed, and they may be insulated from the mounting surface by

material other than sealing compound or by the provision of spacings through air and over surface as

required elsewhere in this standard.

18.1.2 All uninsulated live parts connected to different circuits shall be spaced from one another as

though they were parts of opposite polarity, in accordance with the requirement in 18.2.1 and shall be

judged on the basis of the highest voltage involved.

18.1.3 The spacing at wiring terminals is to be measured with appropriate wires in place and connected

to the terminals as in actual service.

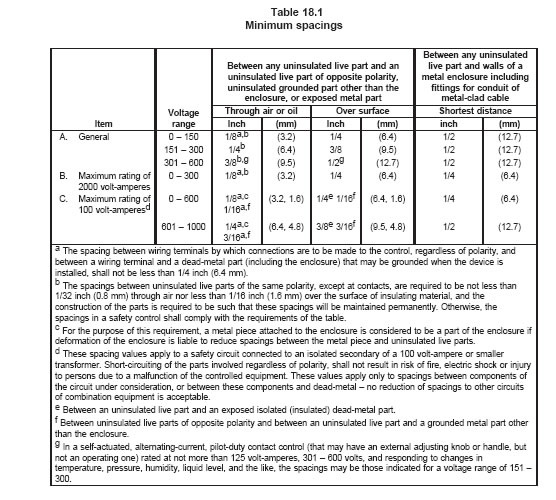

18.2 High-voltage circuits

18.2.1 Except as indicated in 18.2.7, spacings in controls shall not be less than those indicated in Table

18.1 or, at other than field wiring terminals and between uninsulated live parts and a metal enclosure, as

specified in Alternate Spacings – Clearances and Creepage Distances, Section 19. Greater spacings may

be required if the enclosure, because of its size, shape, or the material used, is not considered to be

sufficiently rigid to warrant the minimum spacings.

18.2.2 To determine if a control is within the volt-ampere limitation with respect to the spacing

requirements in Table 18.1, the input voltage is to be considered in accordance with Table 25.1, and the

volt-ampere consumption of the control is to be added to the volt-ampere consumption of the equipment

intended to be controlled. The sum of the inputs to and the switch ratings of the control is the value to be

used to determine if the rating is within the volt-ampere limitation. This principle applies in the case of a

control that does not contain a number of individual components as mentioned in 18.2.5, and also when

individual components are judged in accordance with that paragraph.

18.2.3 The volt-ampere rating of a multiple pole, a double-throw, or a sequencing control is to be taken

as the maximum consumption of the control and the load controlled at any one time.

18.2.4 The volt-ampere equivalent of a horsepower rating is to be taken as the product of the voltage of

the full-load current as specified in and 29.3 and, in the case of a polyphase device, the

appropriate numerical multiplier.

18.2.5 If more than one control is included in one enclosure, the spacing from one control to another, and

from any one control to the enclosure or other uninsulated dead metal part excluding its mounting surface,

is based on the maximum voltage and total volt-ampere rating of the overall assembly and not on the

individual control rating. The inherent spacings within an individual control such as a relay (including

spacings from a live part to the mounting surface other than the enclosure) are judged on the basis of the

volt-amperes consumed and controlled by the individual control.

18.2.6 The inherent spacings within a component, such as a snap switch or lampholder, in other than a

safety circuit, and the inherent spacings within a motor or clock motor, are judged under the requirements

for the component. The spacings from such a component to another component and to the enclosure, and

the spacings at wiring terminals shall be judged in accordance with the requirements in 18.2.1 and Table

18.1.

18.2.7 If required in place of spacings between a magnet-coil winding and other uninsulated live parts or

grounded dead metal parts, the type of insulation may differ from that required by 18.2.8, and the type

and thickness of crossover-lead insulation and insulation under coil terminals secured to the coil winding

may be less than that specified in 18.2.8, provided that the coil is capable of withstanding a dielectric

voltage-withstand test between coil-end leads after breaking the inner coil lead where it enters the layer,

or an equivalent opposite polarity test. The application of the test potential is to be in accordance with 31.1– 31.4.

18.2.8 An insulating lining or barrier of vulcanized fiber or similar materials employed where spacings

would otherwise be insufficient shall not be less than 0.028 inch (0.71 mm) thick and shall be located or

of such material so that it will not be adversely affected by arcing; except that vulcanized fiber not less

than 0.013 inch (0.33 mm) thick may be used in addition to an air spacing of not less than 50 percent of

the spacing required for air alone.

18.2.9 Insulating material having a thickness less than that specified in 18.2.8 may be used if it has

equivalent mechanical and electrical properties.

18.2.10 Unless of a material complying with the requirements in 7.1, a barrier or liner shall be used in

addition to at least 1/32 inch (0.8 mm) air space.

18.2.11 Mica not less than 0.013 inch (0.33 mm) thick may be used in lieu of the through-air spacing

specified in Table 18.1, provided the mica is tightly held in a fixed position by the parts between which the

spacing is required.

18.2.12 Film-coated wire is considered to be the same as an uninsulated live part in determining

compliance of a device with the spacing requirements of this standard.

18.3 Low-voltage circuits

18.3.1 Spacings shall be as indicated in 18.3.2 – 18.3.4 or, at other than field wiring terminals and

between uninsulated live parts and a metal enclosure, as specified in Alternate Spacings – Clearances

and Creepage Distances, Section 19, if a short circuit between the parts involved may result in a risk of

fire or electric shock. Spacings within a low-voltage nonsafety circuit need not be defined if the product

complies with the requirements of the applicable Dielectric Voltage-Withstand Test, Section 31, and the

Operation Test, Section 28.

18.3.2 The spacing between an uninsulated live part and the wall of a metal enclosure, including fittings

for the connection of conduit or metal-clad cable, shall not be less than 1/8 inch (3.2 mm).

18.3.3 The spacing between wiring terminals, regardless of polarity, and between a wiring terminal and

a dead metal part (including the enclosure) that may be grounded when the device is installed shall not

be less than 1/4 inch (6.4 mm).

18.3.4 The spacing between uninsulated live parts, regardless of polarity, and between an uninsulated

live part and a dead metal part, other than the enclosure, that may be grounded when the device is

installed shall not be less than 1/32 inch (0.8 mm), provided that the construction of the parts is such that

spacings will be maintained.

19 Alternate Spacings–Clearances and Creepage Distances

間隙與爬行距離

19.1 As an alternative to the measurement method specified in Spacings, Section 18, the minimum

acceptable clearances (through air spacings) and creepage distances (over surface spacings) may be

evaluated using the Standard for Insulation Coordination Including Clearances and Creepage Distances

for Electrical Equipment, UL 840, as specified in

19.2 –

19.4. The spacing requirements of UL 840 shall

not be used for through air and over surface spacings between the field-wiring terminals and between the

uninsulated live parts and a metal enclosure.

19.2 When applying the requirements in the Standard for Insulation Coordination Including Clearances

and Creepage Distances for Electrical Equipment, UL 840, for unencapsulated assemblies and uncoated

printed wiring boards, pollution degree 1 requirements are applicable to encapsulated assemblies and to

coated printed wiring boards complying with the printed wiring board coating performance test

requirements. The pollution degrees are as defined for Creepage Distances in UL 840.

19.3 For Clearance B (controlled overvoltage) requirements in the Standard for Insulation Coordination

Including Clearances and Creepage Distances for Electrical Equipment, UL 840, the applicable

overvoltage category for line voltage circuits is Category III. Category I is applicable to low-voltage circuits

if short circuit between the parts involved may result in operation of the controlled equipment that

increases the risk of fire or electric shock. Any overvoltage protection device to achieve these categories

shall be provided as an integral part of the control.

19.4 Where measurement of clearances and creepage distances is involved to establish the minimum

spacings, the methods specified for Measurements of Clearance and Creepage Distances in the Standard

for Insulation Coordination Including Clearances and Creepage Distances for Electrical Equipment, UL

840, shall be used.

20 Separation of Circuits電路隔離

20.1 General

20.1.1 Unless provided with insulation rated for the highest voltage involved, insulated conductors of

different circuits (internal wiring) shall be separated by barriers or shall be segregated; and shall, in any

case, be separated or segregated from uninsulated live parts connected to different circuits or opposite

polarity parts of the same circuit.

20.1.2 Segregation of insulated conductors as required by 20.1.1 may be accomplished by clamping,

routing, or equivalent means that provide for permanent separation from insulated or uninsulated live parts

of a different circuit.

20.1.3 Field-installed conductors of any circuit shall be segregated or separated by barriers from:

a) Field- and factory-installed conductors connected to any other circuit, unless the conductors of

both circuits are insulated for the maximum voltage of either circuit.

b) Uninsulated live parts of any other circuit of the control.

c) Any uninsulated live parts the short-circuiting of which may permit operation of the controlled

appliance that increases the risk of fire or electric shock, except that a construction in which

field-installed conductors may make contact with wiring terminals is acceptable, provided that a

conductor with 0.028 inch (0.71 mm) thick thermoplastic insulation rated at least 60°C, 600 V, or

equivalent conductors are or will be installed when wired in accordance with the National

Electrical Code, ANSI/NFPA 70-1993.

20.1.4 Segregation of field-installed conductors from other field-installed conductors and from uninsulated

live parts of the control connected to different circuits may be accomplished by arranging the location of

the openings in the enclosure for the various conductors (with respect to the terminal or other uninsulated

live parts) so that there will be no intermingling of the conductors or parts of different circuits. If the number

of openings in the enclosure does not exceed the minimum required for the proper wiring of the control,

and if each opening is located opposite a set of terminals, it is to be assumed, for the purpose of

determining compliance with 20.1.3, that the conductors entering each opening will be connected to the

terminals opposite the opening. If more than the minimum number of openings are provided, the possibility

of conductors entering at points other than opposite the terminals to which they are intended to be

connected and contacting insulated conductors or uninsulated current-carrying parts connected to a

different circuit is to be investigated. To determine if a device complies with the requirement in 20.1.3, it