Annex C

(normative)

Measurement of clearance and creepage distances

C.1 Measurement

Clearance and creepage distances shall be measured as illustrated in the examples contained

in Examples C.1 to C.14.

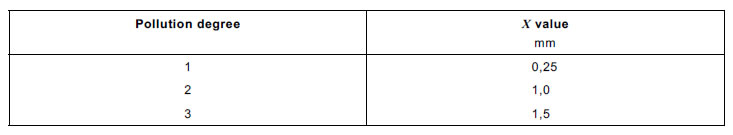

C.2 Relationship of measurement to pollution degree

The “X ” values are a function of pollution degree and shall be as specified in Table C.1. If the

associated permitted clearance is less than 3 mm, the X value is one-third of the clearance.

Table C.1 – Width of grooves by pollution degree

C.3 Examples

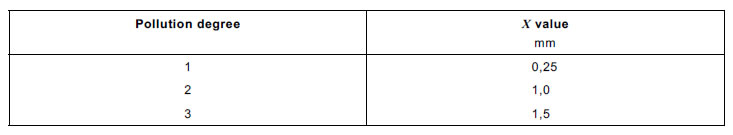

In the Examples C.1 to C.14 below, clearance and creepage distances are denoted as follows:

Condition: the path under consideration includes a parallel, diverging or converging-sided

groove of any depth with a width less than X mm.

Rule: creepage distance and clearance are measured directly across the groove as shown.

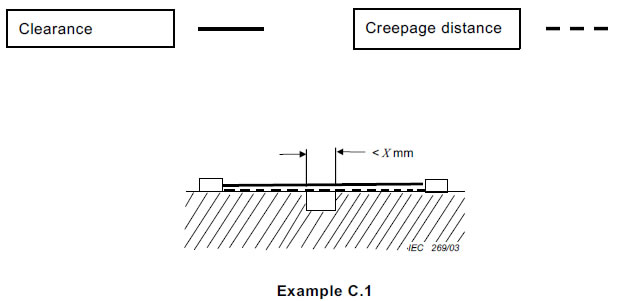

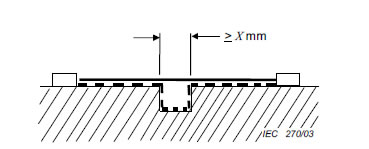

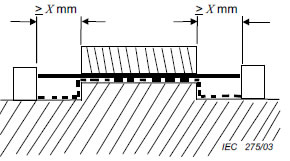

Example C.2

Condition: Path under consideration includes a parallel or diverging-sided groove of any depth

with a width equal to or more than X mm.

Rule: Clearance is the “line of sight” distance. Creepage path follows the contour of the groove

Example C.3

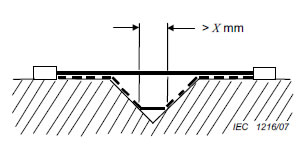

Condition: Path under consideration includes a V-shaped groove with a width greater than

X mm.

Rule: Clearance is the “line of sight” distance. Creepage path follows the contour of the groove

but “short-circuits” the bottom of the groove by X mm link.

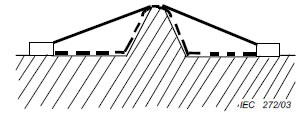

Example C.4

Condition: Path under consideration includes a rib.

Rule: Clearance is the shortest air path over the top of the rib. Creepage path follows the

contour of the rib.

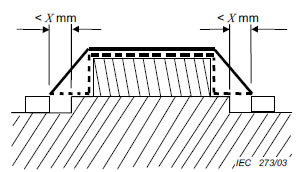

Example C.5

Condition: Path under consideration includes a cemented joint with grooves less than X mm

wide on each side.

Rule: Clearance is the shortest air path over the top of the joint. Creepage distance is

measured directly across the grooves and follows the contour of the joint.

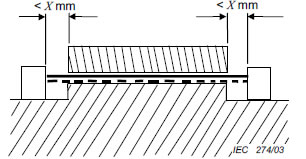

Example C.6

Condition: Path under consideration includes an uncemented joint with grooves less than X mm

wide on each side.

Rule: Creepage and clearance path is the “line of sight” distance shown.

Example C.7

Condition: Path under consideration includes an uncemented joint with grooves equal to or

more than X mm wide on each side.

Rule: Clearance is the “line of sight” distance. Creepage path follows the contour of the

grooves.

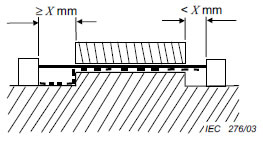

Example C.8

Condition: Path under consideration includes an uncemented joint with a groove on one side

less than X mm wide and the groove on the other side equal to or more than X mm wide.

Rule: Clearance and creepage paths are as shown.

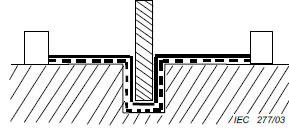

Example C.9

Condition: Path under consideration includes an uncemented barrier when path under the

barrier is less than the path over the barrier.

Example C.10

Condition: Path under consideration includes an uncemented barrier when path over the barrier

is less than the path under the barrier.

Rule: Clearance is the shortest air path over the top of the barrier. Creepage path follows the

contour of the barrier.

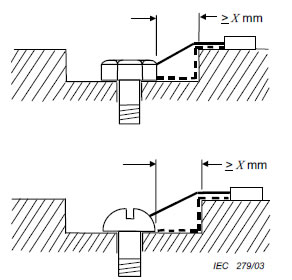

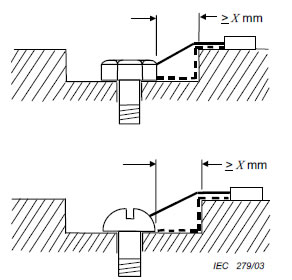

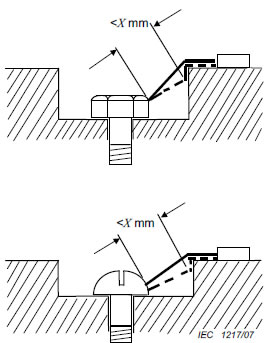

Example C.11

Condition: Path under consideration includes a gap between head of screw and wall of recess

which is equal to or more than X mm wide.

Rule: Clearance is the shortest air path through the gap and over the top surface. Creepage

path follows the contour of the surfaces.

Example C.12

Condition: Path under consideration includes a gap between head of screw and wall of recess

which is less than X mm wide.

Rule: Clearance is the shortest air path through the gap and over the top surface.

Creepage path follows the contour of the surfaces but “short-circuits” the bottom of the recess

by X mm link.

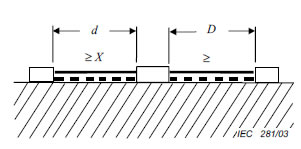

Example C.13

Condition: Path under consideration includes an isolated part of conductive material.

Rule: Clearance and creepage paths are the sum of d plus D.

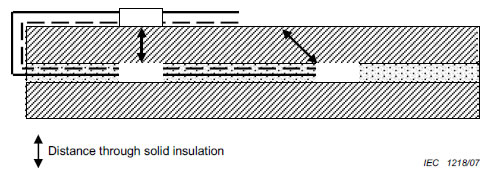

Example C.14

Condition: Path under consideration includes inner layer of PWB.

Rule: For the inner layer(s), the distance between adjacent tracks on the same layer is treated

as creepage distance for pollution degree 1 and clearance as in air (see 4.3.6.8.4.1).