Adjustable speed electrical power drive systems Part 5-2: Safety requirements – Functional

ADJUSTABLE SPEED ELECTRICAL

POWER DRIVE SYSTEMS –

Part 5-2: Safety requirements – Functional

1 Scope

This part of IEC 61 800, which is a product standard, specifies requirements and makes recommendations for the design and development, integration and validation of safety related power drive systems (PDS(SR)) in terms of their functional safety considerations. It applies to adjustable speed electrical power drive systems covered by the other parts of the IEC 61 800 series of standards as referred in IEC 61 800-2.

NOTE 1 The term “integration” refers to the PDS(SR) itself, not to its incorporation into the safety-related application.

NOTE 2 Other parts of IEC 61 800 cover rating specifications, EMC, electrical safety, etc.

This International Standard is applicable where functional safety of a PDS(SR) is claimed and the PDS(SR) is operating mainly in the high demand or continuous mode (see 3.1 5)

While low demand mode operation is possible for a PDS(SR), this standard concentrates on high demand and continuous mode. Safety sub-functions implemented for high demand or continuous mode can also be used in low demand mode. Requirements for low demand mode are given in IEC 61 508 series. Some guidance for the estimation of average probability of dangerous failure on demand (PFD avg ) value is provided in Annex F.

This part of IEC 61 800 sets out safety-related considerations of PDS(SR)s in terms of the framework of IEC 61 508, and introduces requirements for PDS(SR)s as subsystems of a safety-related system. It is intended to facilitate the realisation of the electrical/ electronic/programmable electronic (E/E/PE) parts of a PDS(SR) in relation to the safety performance of safety sub-function(s) of a PDS.

Manufacturers and suppliers of PDS(SR)s by using the normative requirements of this part of IEC 61 800 will indicate to users (system integrator, original equipment manufacturer) the safety performance for their equipment. This will facilitate the incorporation of a PDS(SR) into a safety-related control system using the principles of IEC 61 508, and possibly its specific sector implementations (for example IEC 61 51 1 , IEC 61 51 3, IEC 62061 or ISO 1 3849).

By applying the requirements from this part of the IEC 61 800 series, the corresponding requirements of IEC 61 508 that are necessary for a PDS(SR) are fulfilled.

This part of IEC 61 800 does not specify requirements for:

• the hazard and risk analysis of a particular application;

• the identification of safety sub-functions for that application;

• the initial allocation of SILs to those safety sub-functions;

• the driven equipment except for interface arrangements;

• secondary hazards (for example from failure in a production or manufacturing process);

• the electrical, thermal and energy safety considerations, which are covered in

+IEC 61 800-5-1 ;

• the PDS(SR) manufacturing process;

• the validity of signals and commands to the PDS(SR).

• security aspects (e.g. cyber security or PDS(SR) security of access)

NOTE 3 The functional safety requirements of a PDS(SR) are dependent on the application, and can be considered as a part of the overall risk assessment of the installation. Where the supplier of the PDS(SR) is not responsible for the driven equipment, the installation designer is responsible for the risk assessment, and for specifying the functional and safety integrity requirements of the PDS(SR).

This part of IEC 61 800 only applies to PDS(SR)s implementing safety sub-functions with a SIL not greater than SIL 3.

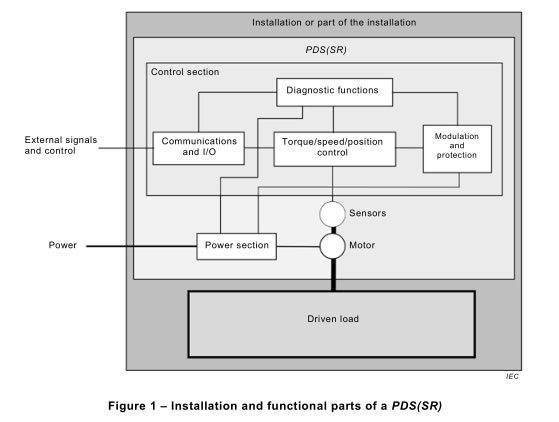

Figure 1 shows the installation and the functional parts of a PDS(SR) that are considered in this part of IEC 61 800 and shows a logical representation of a PDS(SR) rather than its physical description.