3 Terms, definitions and abbreviations

3.1 Alphabetical list of definitions

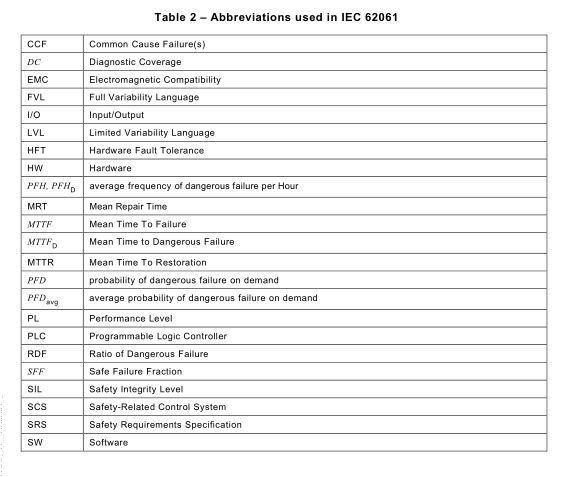

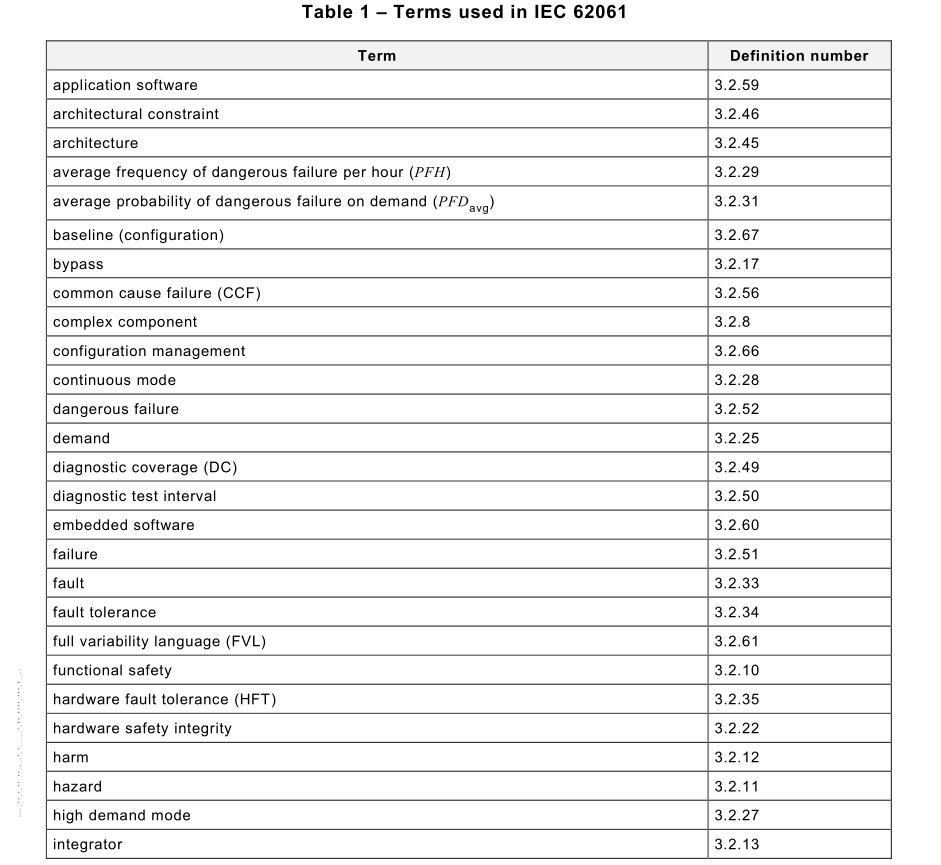

Terms used throughout IEC 62061 are given in Table 1 . Also included are some common

abbreviations related to machinery safety.

3.2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.2.1 machinery

machine

assembly, fitted with or intended to be fitted with a drive system consisting of linked parts or

components, at least one of which moves, and which are joined together for a specific

application

Note 1 to entry: The term “machinery” also covers an assembly of machines which, in order to achieve the same

end, are arranged and controlled so that they function as an integral whole.

[SOURCE: ISO 1 21 00:201 0, 3.1 ]

3.2.2 machine control system

system that responds to input signals from the machinery and/or from an operator and

generates output signals causing the machinery to operate in the desired manner

Note 1 to entry: The machine control system includes input devices and final elements.

[SOURCE: IEC 61 508-4:201 0, 3.3.3, modified – the term defined has been changed, "process"

has been changed to "machinery"]

3.2.3 safety-related control system

SCS

part of the control system of a machine which implements a safety function by one or more

subsystems

Note 1 to entry: SCS is similar to SRECS of the previous edition of this document.

3.2.4

subsystem

entity of the top-level architectural design of a safety-related system where a dangerous failure

of the subsystem results in dangerous failure of a safety function

Note 1 to entry: This differs from common language where “subsystem” may mean any sub-divided part of an entity,

the term “subsystem” is used in this document within a strongly defined hierarchy of terminology: “subsystem” is the

first level subdivision of a system. The parts resulting from further subdivision of a subsystem are called “subsystem

elements”.

Note 2 to entry: A complete subsystem can be made up from a number of identifiable and separate subsystem

elements.

Note 3 to entry: The subsystem specification includes its role in the safety function and its interface with the other

subsystems of the SCS.

Note 4 to entry: One subsystem can be part of several safety functions, e.g. the same combination of contactors

can be used to de-energise a motor either in the event of detection of a person in a danger zone or also in the event

of opening an interlock guard.

[SOURCE: IEC 61 508-4:201 0, 3.4.4, modified – cross references removed and notes added]

3.2.5

pre-designed SCS or subsystem

SCS or subsystem which meets the relevant requirements of a functional safety standard

3.2.6

subsystem element

part of a subsystem, comprising a single component or any group of components

Note 1 to entry: A subsystem element may comprise hardware and software.

Note 2 to entry: Elements that are not directly necessary for the safety function are not included, but may support

it (for example, filters elements, protection against over-voltage) .

Note 3 to entry: A subsystem element is the lowest level of detail to consider when ensuring that the requirements

of a sub-function are met.

3.2.7

low complexity component/subsystem

component/subsystem in which

– the failure modes are well-defined; and

– the behaviour under fault conditions can be completely defined

Note 1 to entry: Behaviour of the low complexity component / subsystem under fault conditions may be determined

by analytical and/or test methods.

Note 2 to entry: Examples of low complexity components / subsystem are limit switches, electro-mechanical relays

or contactors.

[SOURCE: IEC 61 508-4:201 0, 3.4.3, modified – the term defined has been changed, leading to

reformulation of text. Example converted into note 2]

3.2.8

complex component / subsystem

component / subsystem in which

– the failure modes are not well-defined; or

– the behaviour under fault conditions cannot be completely defined

3.2.9

safety

freedom from unacceptable risk

[SOURCE: IEC 61 508-4:201 0, 3.1 .1 1 ]

3.2.1 0

functional safety

part of the overall safety of the machine and the machine control system that depends on the

correct functioning of the SCS and other risk reduction measures

[SOURCE: IEC 61 508-4:201 0, 3.1 .1 2, modified – using terms machine, machine control system

and SCS]

3.2.1 1

hazard

potential source of harm

Note 1 to entry: The term hazard can be qualified in order to define its origin or the nature of the expected harm

(e.g. electric shock hazard, crushing hazard, cutting hazard, toxic hazard, fire hazard)

[SOURCE: ISO 1 21 00:201 0, 3.6, modified – note 1 has been modified and notes 2 and 3

deleted]

3.2.1 2

harm

injury or damage to the health of people

[SOURCE: ISO/IEC Guide 51 :201 4, 3.1 , modified – without damage to property or the

environment]

3.2.1 3

integrator

entity who designs, manufactures or assembles an integrated manufacturing system and is

responsible for the safety strategy, including the protective measures, control interfaces and

interconnections of the control system

Note 1 to entry: The integrator may be for example a manufacturer, assembler, engineering company, or entity with

the overall responsibility for the machine.

[SOURCE: ISO 1 1 1 61 :2007, 3.1 0, modified – "provides" has been deleted, last entry in note

reformulated]

3.2.1 4

protective measure

measure intended to achieve risk reduction

[SOURCE: ISO 1 21 00:201 0, 3.1 9, modified – bullet list removed]

3.2.1 5

risk

combination of the probability of occurrence of harm and the severity of that harm

[SOURCE: ISO/IEC Guide 51 :201 4, 3.9 modified – note to entry removed]

3.2.1 6

muting

temporary automatic suspension of a safety function(s)

Note 1 to entry: Other means are used to maintain the safety level.

[SOURCE: ISO 1 3849-1 :201 5, 3.1 .8, modified – "by the SRP/CS" has been deleted, note

added]

3.2.1 7

bypass

action or facility to prevent all or parts of the SCS functionality from being executed

Note 1 to entry: Examples of bypassing include:

– the input signal is blocked from the trip logic while still presenting the input parameters and alarm to the operator;

– the output signal from the trip logic to a final element is held in the normal state preventing final element

operation;

– a physical bypass line is provided around the final element;

– preselected input state (e.g., on/off input) or set is forced by means of an engineering tool (e.g., in the application

program).

Note 2 to entry: Other terms are also used to refer to bypassing, such as override, defeat, disable, force, or inhibit

or muting.

[SOURCE: IEC 61 51 1 -1 :201 6, 3.2.4, modified – SIS replaced by SCS]

3.2.1 8

safety function

function implemented by an SCS with a specified integrity level that is intended to maintain the

safe condition of the machine or prevent an immediate increase of the risk(s) in respect of a

specific hazardous event

Note 1 to entry: This term is used instead of “safety-related control function (SRCF)” of IEC 62061 :201 5. This

definition differs from ISO 1 21 00 because this document addresses risk reduction performed by SCS.

Note 2 to entry: A safety function is typically starting with a detection and evaluation of an ‘initiation event’ and

ending with an output causing a reaction of a ‘machine actuator’.

Note 3 to entry: Parts of machine operating function(s), e.g. the reaction of a machine actuator, can also be part of

safety function(s).

[SOURCE: IEC 61 508-4:201 0, 3.5.1 , modified – terminology adapted to machinery, other risk

reduction measures deleted, example deleted, notes added]

3.2.1 9

(SCS) diagnostic function

function intended to detect faults in the SCS and initiate a specified fault reaction function when

a fault is detected

Note 1 to entry: This function is intended to detect faults that could lead to a dangerous failure of a safety function

and initiate a specified fault reaction function.

3.2.20

(SCS) fault reaction function

function that is initiated when a fault within an SCS is detected by the SCS diagnostic function

3.2.21

safety integrity

probability of an SCS or its subsystem satisfactorily performing the required safety function

under all stated conditions within a stated period of time

Note 1 to entry: The higher the level of safety integrity of the item, the lower the probability that the item will fail to

carry out the required safety function.

Note 2 to entry: Safety integrity comprises hardware safety integrity and systematic safety integrity.

[SOURCE: IEC 61 508-4:201 0, 3.5.4, modified – terminology adapted to machinery, notes 2, 3,

5 deleted]

3.2.22

hardware safety integrity

part of the safety integrity of an SCS or its subsystems relating to random hardware failures in

a dangerous mode of failure

Note 1 to entry: The term relates to failures in a dangerous mode, that is, those failures of a safety-related system

that would impair its safety integrity.

Note 2 to entry: Hardware safety integrity includes architectural constraints.

[SOURCE: IEC 61 508-4:201 0, 3.5.7 – terminology adapted to machinery, note 1 shortened,

note 2 added]

3.2.23

systematic safety integrity

part of the safety integrity of an SCS or its subsystems relating to its resistance to systematic

failures in a dangerous mode

Note 1 to entry: Systematic safety integrity cannot usually be quantified precisely.

Note 2 to entry: Requirements for systematic safety integrity apply to both hardware and software aspects of an

SCS or its subsystems.

[SOURCE: IEC 61 508-4:201 0, 3.5.6, modified – terminology adapted to machinery, note 1

shortened, note 2 added]

3.2.24

safety integrity level

SIL

discrete level (one out of a possible three) for describing the capability to perform a safety

function where safety integrity level three has the highest level of safety integrity and safety

integrity level one has the lowest

3.2.25

demand

event that causes the SCS to perform a safety function

Note 1 to entry: Demand mode means that a safety function is only performed on request (demand) in order to

transfer the machine into a specified state. The SCS does not influence the machine until there is a demand on the

safety function.

Note 2 to entry: Demand rate (DR) or the frequency of demands is one of the main factor that is considered for

assessing the demand mode, low or high. For this particular purpose, the demand rate (DR) can be identified with

the rate of events, where harm would occur without intervention of the safety function. This rate may be lower than

an actual rate of triggering the safety function during operation.

Note 3 to entry: For an emergency stop function, the demand mode is not defined. To determine the achieved SIL,

the principle for evaluation of the selected demand mode of the other functions is usually applicable.

3.2.26

low demand mode

mode of operation in which the frequency of demands of a safety function is no greater than

one per year

[SOURCE: IEC 61 508-4:201 0, 3.5.1 6, modified – low demand extracted from definition of

"mode of operation"]

3.2.27

high demand mode

mode of operation in which the frequency of demands of a safety function is greater than one

per year

Note 1 to entry: Continuous mode means that a safety function is performed continuously, i.e. the SCS is

continuously controlling the machine and a (dangerous) failure of its function can result in a hazard.

Note 2 to entry: The distinction between high demand and continuous mode is relevant for the qualification of

diagnostic measures (refer to 7.4.3 and 7.4.4). It is not relevant for target failure measure and SIL assignment.

[SOURCE: IEC 61 508-4:201 0, 3.5.1 6, modified – high demand extracted from definition of

"mode of operation", notes added]

3.2.28

continuous mode

mode of operation where the safety function retains the machinery in a safe state as a part of

normal operation

Note 1 to entry: Continuous mode means that a safety function is performed continuously, i.e. the SCS is

continuously controlling the machine and a (dangerous) failure of its function can result in a hazard.

Note 2 to entry: The distinction between high demand and continuous mode is relevant for the qualification of

diagnostic measures (refer to 7.4.3 and 7.4.4). It is not relevant for target failure measure and SIL assignment”.

[SOURCE: IEC 61 508-4:201 0, 3.5.1 6, modified – high demand extracted from definition of

"mode of operation", notes added]

3.2.29

average frequency of a dangerous failure per hour

PFH or PFH D

average frequency of dangerous failure of an SCS to perform a specified safety function over a

given period of time

Note 1 to entry: Both terms PFH and PFH D correspond to the probability of dangerous failures per hour

(IEC 62061 :2005+AMD1 :201 2+AMD2:201 5).

Note 2 to entry: The term “average probability of dangerous failure per hour” is not used in this edition anymore but

the acronym PFH has been retained but when it is used it means “average frequency of dangerous failure [h]".

[SOURCE: IEC 61 508-4:201 0, 3.6.1 9, modified – terminology adapted to machinery, existing

notes deleted, new notes added]

3.2.30

probability of dangerous failure on demand

PFD

safety unavailability (see IEC 60050-1 92) of an SCS to perform the specified safety function

when a demand occurs from the machinery or machinery control system

Note 1 to entry: The [instantaneous] unavailability (as per IEC 60050-1 92) is the probability that an item is not in a

state to perform a required function under given conditions at a given instant of time, assuming that the required

external resources are provided. It is generally noted by U (t).

Note 2 to entry: The [instantaneous] availability does not depend on the states (running or failed) experienced by

the item before it. It characterizes an item which only has to be able to work when it is required to do so, for example,

an SCS working in low demand mode.

Note 3 to entry: If periodically tested, the PFD of an SCS is, in respect of the specified safety function, represented

by a saw tooth curve with a large range of probabilities ranging from low, just after a test, to a maximum just before

a test.

[SOURCE: IEC 61 508-4:201 0, 3.6.1 7, modified – terminology adapted to machinery]

3.2.31

average probability of dangerous failure on demand

PFD avg

mean unavailability (see IEC 60050-1 92) of an SCS to perform the specified safety function

when a demand occurs from the machinery or machinery control system as an average over

time

Note 1 to entry: The mean unavailability over a given time interval [t1 , t2] is generally noted by U (t1 , t2).

Note 2 to entry: Two kind of failures contribute to PFD and PFD avg : the dangerous undetected failures occurred

since the last proof test and genuine on demand failures caused by the demands (proof tests and safety demands)

themselves. The first one is time dependent and characterized by their dangerous failure rate λ DU (t) whilst the second

one is dependent only on the number of demands and is characterized by a probability of failure per demand (denoted

by γ).

Note 3 to entry: As genuine on demand failures cannot be detected by tests, it is necessary to identify them and

take them into consideration when calculating the target failure measures.

[SOURCE: IEC 61 508-4:201 0, 3.6.1 8, modified – terminology adapted to machinery]

3.2.32

target failure measure

intended PFH or PFD avg to be achieved to meet a specific safety integrity requirement(s)

Note 1 to entry: Target failure measure is specified in terms of:

– the average probability of a dangerous failure of the safety function on demand, (for a low demand mode of

operation);

– the average frequency of a dangerous failure [h -1 ] (for a high demand mode of operation or a continuous mode

of operation).

[SOURCE: IEC 61 508-4:201 0, 3.5.1 7, modified – "target probability of dangerous mode

failures" changed to "intended PFH or PFD avg ", bullet list moved to note 1 , existing note deleted]

3.2.33

fault

abnormal condition that may cause a reduction in, or loss of, the capability of an SCS, a

subsystem, or a subsystem element to perform a required function

Note 1 to entry: In IEC 60050-1 92, 1 92-04-01 a fault of an item is described as inability to perform as required, due

to an internal state.

[SOURCE: IEC 61 508-4:201 0, 3.6.1 , modified – terminology adapted to machinery, note

shortened]

3.2.34

fault tolerance

ability of an SCS, a subsystem, or subsystem element to continue to perform a required function

in the presence of faults or failures

[SOURCE: IEC 61 508-4:201 0, 3.6.3, modified – terminology adapted to machinery]

3.2.35

hardware fault tolerance

HFT

property of a subsystem to potentially lose the safety function upon at least N+1 faults

Note 1 to entry: A hardware fault tolerance of N means that N+1 faults of a subsystem could cause a loss of the

safety function.

[SOURCE: IEC 61 508-2:201 0, derived from 7.4.4.1 .1 ]

3.2.36

sub-function

part of a safety function whose failure can result in a failure of the safety function

Note 1 to entry: In this document, a safety function can be seen as a logical AND of the sub-functions.

3.2.37

mean time to failure

MTTF

expectation of the mean time to failure

Note 1 to entry: MTTF is normally expressed as an average value of expectation of the time to failure.

[SOURCE: IEC 60050-1 92, 1 92-05-1 1 , modified – note added and original notes removed]

3.2.38

mean time to dangerous failure

MTTF D

expectation of the mean time to dangerous failure

[SOURCE: Definition derived from IEC 60050-1 92, 1 92-05-1 1 , modified – restricted to

dangerous failures]

3.2.39

mean time to restoration

MTTR

expected time to achieve restoration after a fault has occurred in a safety function.

Note 1 to entry: MTTR encompasses:

• the time to detect the failure (a); and

• the time spent before starting the repair (b); and

• the effective time to repair (c); and

• the time before the component is put back into operation (d).

The start time for (b) is the end of (a); the start time for (c) is the end of (b); the start time for (d) is the end of (c).

Note 2 to entry: During this time the machine can continue to operate

[SOURCE: IEC 61 508-4:201 0, 3.6.21 , modified – terminology adapted to machinery and more

details added to definition]

3.2.40

mean repair time

MRT

mean repair time after a fault has been detected in a safety function and machine continues to

operate

Note 1 to entry: MRT encompasses:

• the time spent before starting the repair (b); and

• the effective time to repair (c); and

• the time before the component is put back into operation (d).

Note 2 to entry: Depending on the type of detected fault and the fault reaction, the numerical values for MRT and

MTTR can be different.

[SOURCE: IEC 61 508-4:201 0, 3.6.22, modified – terminology adapted to machinery and more

details added to definition, note 1 made similar to 3.2.39, note 2 added]

3.2.41

process safety time

period of time between a failure, that has the potential to give rise to a hazardous event,

occurring in the machinery or machinery control system and the time by which action has to be

completed in the machinery to prevent the hazardous event occurring

Note 1 to entry: It is foreseen that the safety function detects the failure and completes its action soon enough to

prevent the hazardous event taking into account any process lag (e.g. stopping times).

[SOURCE: IEC 61 508-4:201 0, 3.6.20 modified – terminology adapted to machinery, note 1

added]

3.2.42

useful lifetime

minimum elapsed time between the installation of the SCS or subsystem or subsystem element

and the point in time when component failure rates of the SCS or subsystem or subsystem

element can no longer be predicted, with any accuracy

Note 1 to entry: Typically it will be 20 years or less unless the manufacturers of the SCS and its subsystems can

justify a longer lifetime by providing evidence, based on calculations, showing that reliability data is valid for the

longer lifetime.

[SOURCE: IEC 61 1 31 -6:201 2, 3.57, modified – terminology adapted to machinery, note 1

added, example deleted]

3.2.43

well-tried component

for a safety-related application, component for a safety-related application which has been

either

a) widely used in the past with successful results in similar safety-related applications as given

as well-tried components in the informative annexes of ISO 1 3849-2, or

b) made and verified using principles which demonstrate its suitability and reliability for safety

-related applications

Note 1 to entry: ISO 1 3849-2 lists a variety of components and the conditions for specific technologies under which

the component can be considered well-tried.

Note 2 to entry: Newly developed components may be considered as equivalent to “well-tried” if they fulfil the

conditions of b).

Note 3 to entry: The decision to accept a particular component as being “well-tried” depends on the application,

e.g. owing to the environmental influences and can be impacted by product or manufacturer changes.

Note 4 to entry: Complex electronic components (e.g. PLC, microprocessor, application-specific integrated circuit)

cannot be considered as equivalent to “well tried”.

Note 5 to entry: A well-tried component is not a proven in use component.

3.2.44

well-tried safety principles

principles that have proved effective in the design or integration of safety-related control

systems in the past, to avoid or control critical faults or failures which can influence the

performance of a safety function

Note 1 to entry: Newly developed safety principles can be considered as equivalent to “well-tried” if they are verified

using principles which demonstrate their suitability and reliability for safety-related applications.

Note 2 to entry: Well-tried safety principles are effective not only against random hardware failures, but also against

systematic failures which may creep into the product at some point in the course of the product life cycle, e.g. faults

arising during product design, integration, modification or deterioration.

Note 3 to entry: Tables A.2, B.2, C.2 and D.2 in the informative annexes of ISO 1 3849-2:201 2 address well-tried

safety principles for different technologies.

[SOURCE: Definition derived from ISO 1 3849-1 :201 5]

3.2.45

architecture

specific configuration of hardware and software elements in an SCS

[SOURCE: IEC 61 508-4:201 0, 3.3.4, modified – terminology adapted to machinery]

3.2.46

architectural constraint

set of architectural requirements that limit the SIL that can be claimed for a subsystem

3.2.47

proof test

periodic test that can detect dangerous undetected faults and degradation in an SCS and its

subsystems so that, if necessary, the relevant parts of the SCS and its subsystems can be

restored to an “as new” condition or as close as practical to this condition

Note 1 to entry: A proof test is intended to confirm that relevant parts of an SCS are in a condition that assures the

specified safety integrity.

Note 2 to entry: The effectiveness of the proof test will be dependent both on failure coverage and repair

effectiveness. In practice, detecting 1 00 % of the degradation that could lead to the hidden dangerous failures later

on is not easily achieved. For complex elements or safety features that are difficult to verify, a proof test coverage

of 1 00 % cannot be usually obtained.

[SOURCE: IEC 61 508-4:201 0, 3.8.5, modified – terminology adapted to machinery, notes 1 , 3,

4 deleted, new note 1 added, note 2 shortened]

3.2.48

proof test coverage

term given to the percentage of dangerous undetected failures that are detected by a defined

proof test procedure

Note 1 to entry: It measures the effectiveness of a proof test and ranges from 0 % to 1 00 % (perfect proof-test).

Note 2 to entry: For example, a PTC of 95 % states that 95 % of all possible undetected failures will be detected

during the proof test. It doesn’t include aging or degradation not directly related to the safety function failure.

Note 3 to entry: The PTC can be estimated by the means of Failure Mode and Effects Analysis (FMEA) in

conjunction with engineering judgement based on sound evidence.

3.2.49

diagnostic coverage

DC

fraction of dangerous failures detected by automatic on-line diagnostic tests

Note 1 to entry: The fraction of dangerous failures is computed by using the dangerous failure rates associated with

the detected dangerous failures divided by the total rate of dangerous failures.

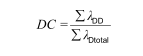

Note 2 to entry: The dangerous failure diagnostic coverage is computed using the following equation, where DC is

the diagnostic coverage, λ DD is the detected dangerous failure rate and λ Dtotal is the total dangerous failure rate:

Note 3 to entry: This definition is applicable providing the individual components have constant failure rates.

[SOURCE: IEC 61 508-4:201 0, 3.8.6, modified – part of the definition has been moved to a note

to entry]

3.2.50

diagnostic test interval

interval between on-line tests to detect faults in a subsystem that has a specified diagnostic

coverage

[SOURCE: IEC 61 508-4:201 0, 3.8.7, modified – replacing safety-related system by subsystem]

3.2.51

failure

termination of the ability of an item (SCS, a subsystem or a subsystem element) to perform a

required function

Note 1 to entry: Failures are either random (in hardware) or systematic (in hardware or software).

Note 2 to entry: After a failure, the item has a fault.

Note 3 to entry: “Failure” is an event, as distinguished from “fault”, which is a state.

Note 4 to entry: The concept of failure as defined does not apply to items consisting of software only.

[SOURCE: IEC 61 508-4:201 0, 3.6.4, modified and ISO 1 21 00-1 :201 0, 3.32]

3.2.52

dangerous failure

failure of an SCS, a subsystem, or a subsystem element that plays a part in implementing the

safety function that:

a) prevents a safety function from operating when required (demand mode) or causes a safety

function to fail (continuous mode) such that the machine is put into a hazardous or

potentially hazardous state; or

b) decreases the probability that the safety function operates correctly when required

[SOURCE: IEC 61 508-4:201 0, 3.6.4, modified – terminology adapted to machinery and figure

replaced by textual description and ISO 1 21 00-1 :201 0, 3.34]

3.2.53

safe failure

failure of an SCS, a subsystem, or a subsystem element that plays a part in implementing the

safety function that:

a) results in the spurious operation of the safety function to put the machine (or part thereof)

into a safe state or maintain a safe state; or

b) increases the probability of the spurious operation of the safety function to put the machine

(or part thereof) into a safe state or maintain a safe state

[SOURCE: IEC 61 508-4:201 0, 3.6.8, modified – terminology adapted to machinery]

3.2.54

safe failure fraction

SFF

fraction of the overall failure rate of a subsystem that does not result in a dangerous failure

Note 1 to entry: The diagnostic coverage (if any) of each subsystem in SCS is taken into account in the calculation

of the probability of random hardware failures. The safe failure fraction is taken into account when determining the

architectural constraints on hardware safety integrity (see 7.4).

Note 2 to entry: “No effect failures” and “no part failures” (see IEC 61 508-4) is not used for SFF calculations.

3.2.55

ratio of dangerous failure

RDF

fraction of the overall failure rate of an element that can result in a dangerous failure

3.2.56

common cause failure

CCF

failure, that is the result of one or more events, causing concurrent failures of two or more

separate channels in a multiple channel subsystem, leading to failure of a safety function

[SOURCE: IEC 61 508-4:201 0, 3.6.1 0, modified – system failure replaced by failure of a safety

function]

3.2.57

random hardware failure

failure occurring at a random time, which results from one or more of the possible degradation

mechanisms in the hardware

[SOURCE: IEC 61 508-4:201 0, 3.6.5, modified – notes removed]

3.2.58

systematic failure

failure, related in a deterministic way to a certain cause, which can only be eliminated by a

modification of the design or of the manufacturing process, operational procedures,

documentation or other relevant factors

Note 1 to entry: Corrective maintenance without modification will usually not eliminate the failure cause.

Note 2 to entry: A systematic failure can be induced by simulating the failure cause.

Note 3 to entry: Examples of causes of systematic failures include human error in

• the safety requirements specification;

• the design, manufacture, installation and/or operation of the hardware;

• the design and/or implementation of the software.

[SOURCE: IEC 61 508-4:201 0, 3.6.6, modified – note 3 slightly changed, note 4 removed]

3.2.59

application software

software specific to the application, that is implemented by the designer of the SCS, generally

containing logic sequences, limits and expressions that control the appropriate input, output,

calculations, and decisions necessary to meet the SCS functional requirements

3.2.60

embedded software

software, supplied as part of a pre-designed subsystem, that is not intended to be modified and

that relates to the functioning of, and services provided by, the SCS or subsystem, as opposed

to the application software

Note 1 to entry: Firmware and system software are examples of embedded software.

3.2.61

full variability language

FVL

type of language that provides the capability to implement a wide variety of functions and

applications

Note 1 to entry: Typical example of systems using FVL are general-purpose computers.

Note 2 to entry: FVL is normally found in embedded software and is rarely used in application software.

Note 3 to entry: FVL examples include: Ada, C, Pascal, Instruction List, assembler languages, C++, Java, SQL.

[SOURCE: IEC 61 51 1 -1 :201 6, 3.2.75.3, modified – first part of definition supressed and link to

process sector deleted]

3.2.62

limited variability language

LVL

type of language that provides the capability to combine predefined, application specific, library

functions to implement the safety requirements specifications

Note 1 to entry: A LVL provides a close functional correspondence with the functions required to achieve the

application.

Note 2 to entry: Typical examples of LVL are given in IEC 61 1 31 -3. They include ladder diagram, function block

diagram and sequential function chart. Instruction lists and structured text are not considered to be LVL.

Note 3 to entry: Typical example of systems using LVL: Programmable Logic Controller (PLC) configured for

machine control.

[SOURCE: IEC 61 51 1 -1 :201 6, 3.2.75.2, modified – note 1 turned into definition, note 2 deleted,

note 3 replaced]

3.2.63

safety-related software

software that is used to implement safety functions in a safety-related system

3.2.64

verification

confirmation by examination (e.g. tests, analysis) that the SCS, its subsystems or subsystem

elements meet the requirements set by the relevant specification

EXAMPLE: Verification activities include

• reviews on outputs (documents from all phases) to ensure compliance with the objectives and requirements of

the phase, taking into account the specific inputs to that phase;

• design reviews;

• tests performed on the designed products to ensure that they perform according to their specification;

• integration tests performed where different parts of a system are put together in a step-by-step manner and by

the performance of environmental tests to ensure that all the parts work together in the specified manner.

[SOURCE: IEC 61 508-4:201 0, 3.8.1 , modified – terminology adapted to machinery, note

deleted]

3.2.65

validation (of the safety function)

confirmation by examination (e.g. tests, analysis) that the SCS meets the functional safety

requirements of the specific application

[SOURCE: IEC 61 508-4:201 0, 3.8.2, modified – terminology adapted to machinery, notes

deleted]

3.2.66

configuration management

discipline of identifying the components of an evolving system for the purposes of controlling

changes to those components and maintaining continuity and traceability throughout the

lifecycle

[SOURCE: IEC 61 508-4:201 0, 3.7.3, modified – note removed]

3.2.67

baseline (configuration)

well-defined set of elements (hardware, software, documentation, tests, etc.) of an SCS at a

specific point in time.

Note 1 to entry: A baseline serves as a basis for verification, validation, modification and changes.

Note 2 to entry: If an element is changed, the status of the baseline is intermediate until a new baseline is defined.

3.2.68

safe state

state of the machine when safety is achieved

Note 1 to entry: The safe state doesn’t include the restoration of initial equipment failures.

[SOURCE: IEC 61 508-4:201 0, 3.1 .1 3, modified – terminology adapted to machinery, original

note deleted, note 1 added]

3.2.69

security

1 ) measures taken to protect a system

2) condition of a system that results from the establishment and maintenance of measures to

protect the system

3) condition of system resources being free from unauthorized access and from unauthorized

or accidental change, destruction, or loss

4) capability of a computer-based system to provide adequate confidence that unauthorized

persons and systems can neither modify the software and its data nor gain access to the

system functions, and yet to ensure that this is not denied to authorized persons and

systems

5) prevention of illegal or unwanted penetration of, or interference with the proper and intended

operation of an industrial automation and control system

Note 1 to entry: Measures can be controls related to physical security (controlling physical access to computing

assets) or logical security (capability to login to a given system and application).

[SOURCE: IEC TS 62443-1 -1 :2009, 3.2.99]

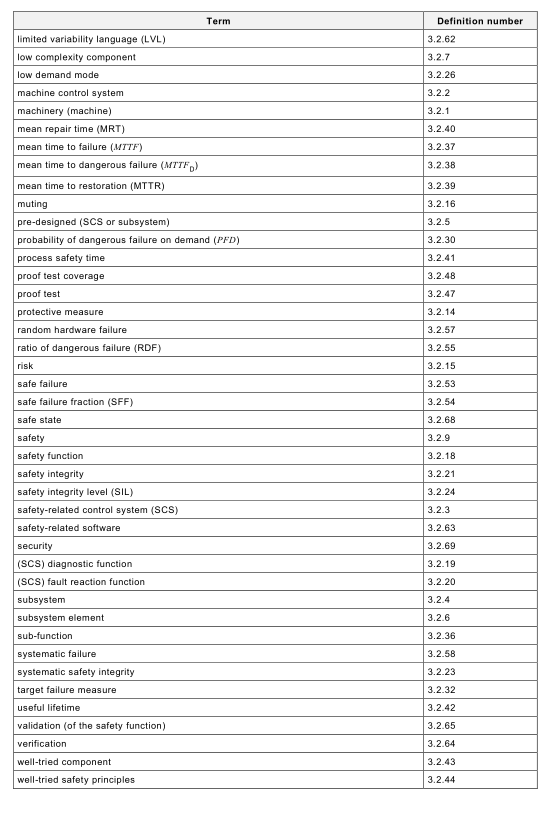

3.3 Abbreviations

Abbreviations used in this document are shown in Table 2.