Annex H

(informative)

Simplified approaches to evaluate the PFH value of a subsystem

H.1 Table allocation approach

The following procedure allows evaluating the PFH value of a subsystem:

1 ) Selection of the used architecture of a not-pre-designed subsystem based on the DC(s) per

channel;

NOTE 1 A pre-designed subsystem is characterized by a SIL with a PFH value (see also 6.2). A not-pre-

designed subsystem claims a maximum SIL based on the architectural constraints (see 7.4).

Where the DCs per channel are different, either the lowest DC per channel may be used as

a worst case approach, or the arithmetic average of DC per channel of both channels.

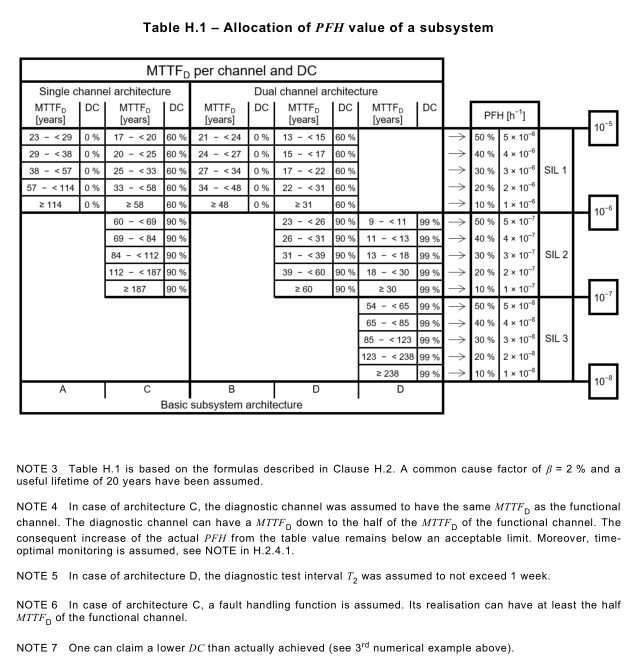

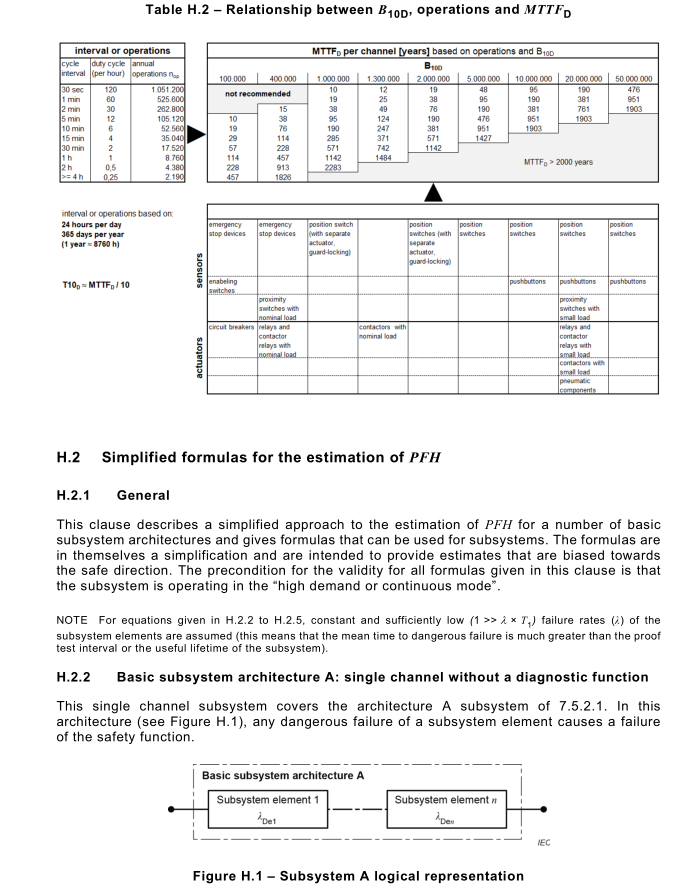

2) Determination of PFH value with Table H.1 and Table H.2 for not-pre-designed subsystems:

– using Table H.1 for components qualified by MTTF D per channel and DC to allocate the

PFH value within a range of 1 0 %, 20 %, 30 %, 40 % or 50 % of the limit of the respective

required SIL, or

– using Table H.2 for components qualified by B 1 0D and equation (7) in 7.3.4.2 to

determine the MTTF D per channel and then, by use of Table H.1 , allocating the PFH

value within a range of 1 0 %, 20 %, 30 %, 40 % or 50 % of the limit of the respective

required SIL.

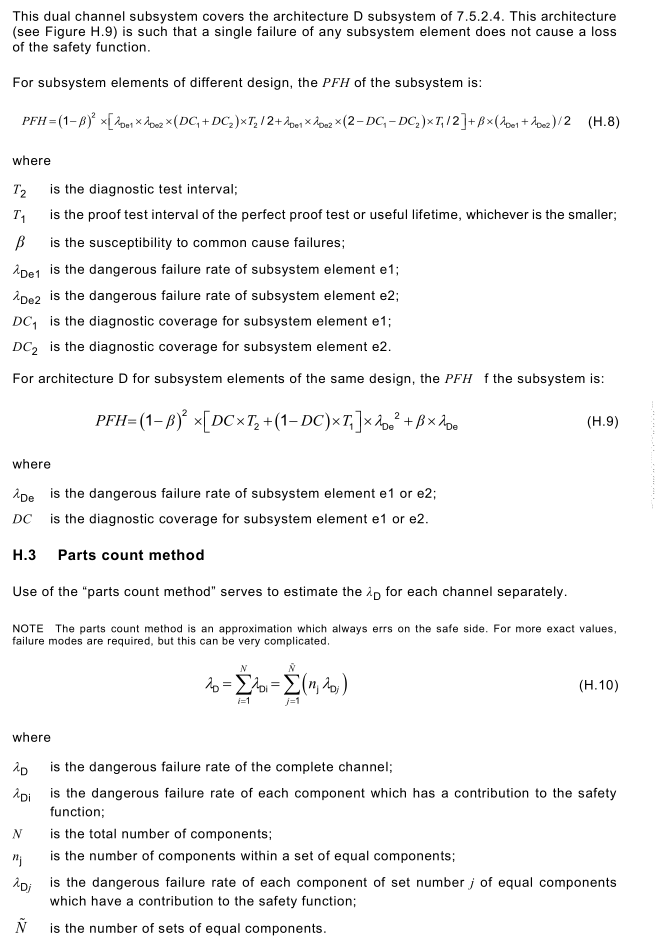

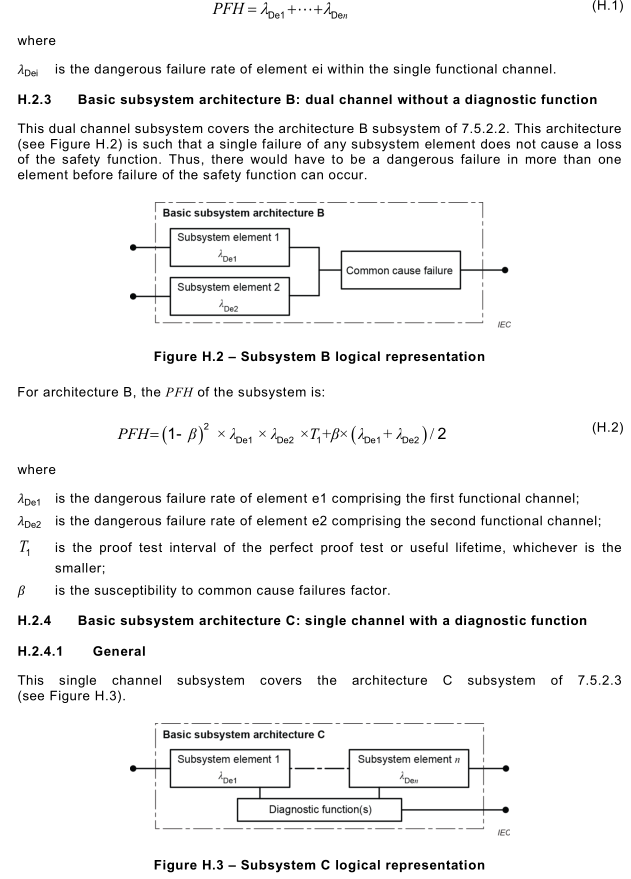

The safety function is performed by a single channel comprising the elements e1 to en. Any

undetected dangerous fault of a subsystem element leads to a dangerous failure of the safety

function.

Where a fault of a subsystem element is detected, the diagnostic function(s) initiates a fault

reaction function (see 7.4.3).

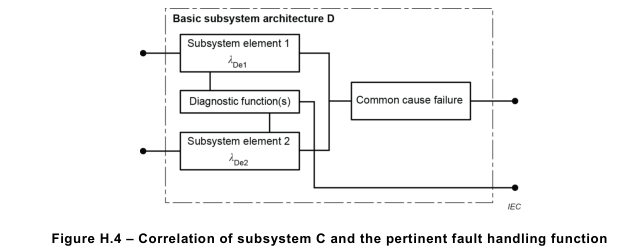

In the following, the notion of fault handling function is used. The fault handling function

comprises both the fault detection function and the fault reaction function, see Figure H.4.

All approaches of H.2.4 for the calculation of PFH assume time-optimal fault handling. Time-

optimal fault handling of a subsystem element can be assumed if:

• the diagnostic rate is at least a factor of 1 00 higher than the demand rate of the safety

function and the time needed for the fault reaction is sufficiently short to bring the system

to a safe state before a hazardous event occurs; or

• the fault handling is performed immediately upon any potential demand of the safety function

and the time needed to detect a detectable fault and to bring the system to a safe state is

shorter than the process safety time; or

• the fault handling is performed continuously and the time needed to detect a detectable fault

and to bring the system to a safe state is shorter than the process safety time; or

• the fault handling is performed periodically and the sum of the test interval, the time needed

to detect a detectable fault and time needed to bring the system to a safe state is shorter

than the process safety time.

NOTE Although the failure of the fault handling function will not cause a failure of the safety function, the elements

contributing to the fault handling function are assigned a dangerous failure rate containing the letter D in the index

of λ . Dangerous failures in this sense are failures that lead to a loss of the fault handling function. The dangerous

failure rate of elements involved in the fault handling function does not cover failures which lead to a fault reaction

although there is no failure of the functional channel (so-called “false trips”).

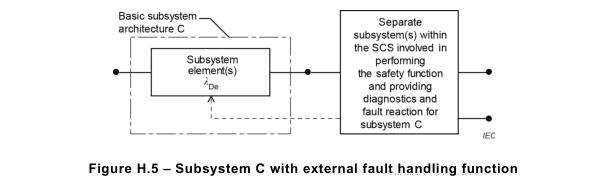

H.2.4.2 External fault handling function

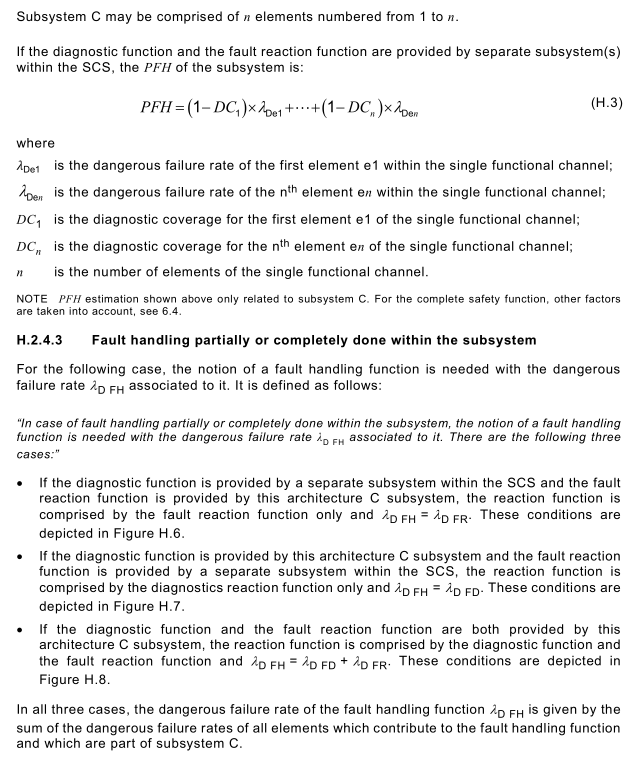

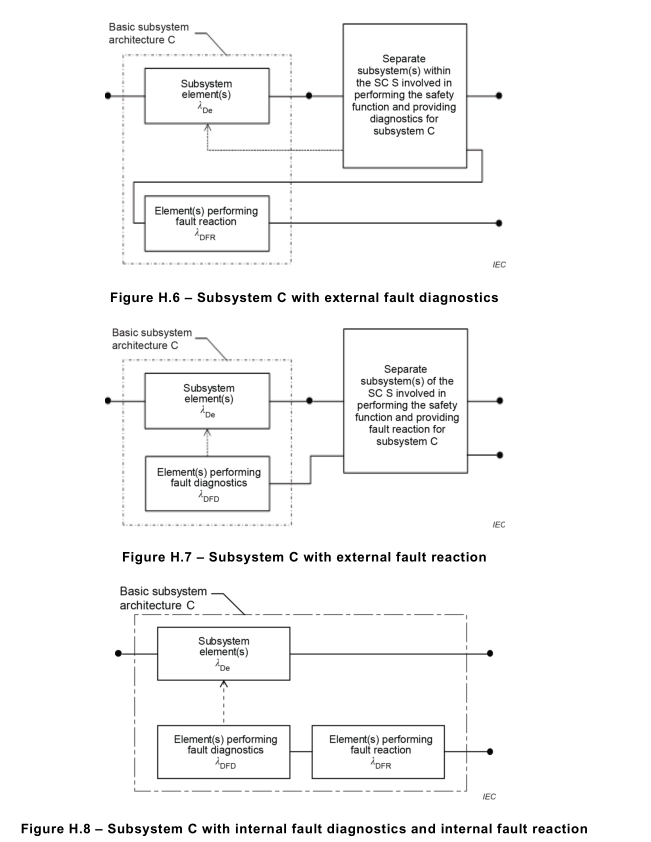

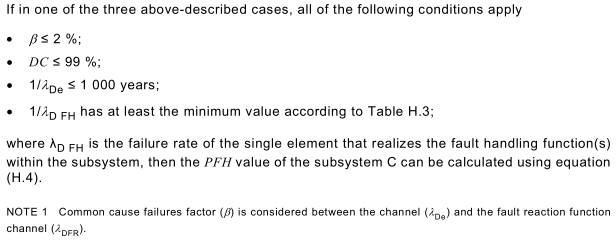

The fault handling function may be completely performed by a separate subsystem(s) of the

SCS which is also involved in performing the safety function, thus contributing to its PFH. These

conditions are depicted in Figure H.5.