3 Terms, definitions, symbols and abbreviated terms

3.1Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 12100:2010 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

safety–related part of a control system

SRP/CS part of a control system that performs a safety function, starting from a safety-related input(s) to generating a safety-related output(s)

Note 1 to entry: The safety-related parts of a control system start at the point where the safety-related inputs are initiated (including, for example, the actuating cam and the roller of the position switch) and end at the output of

the power control elements (including, for example, the main contacts of a contactor).

3.1.2

machine control system

system which responds to input signals from parts of machine elements, operators, external control

equipment or any combination of these and generates output signals causing the machine to behave in

the intended manner

Note 1 to entry: The machine control system can use any technology or any combination of different technologies

(e.g. electrical/electronic, hydraulic, pneumatic and mechanical).

3.1.3

safety requirements specification

SRS

specification containing the requirements for the safety functions that have to be met by the safety-

related control system in terms of characteristics of the safety functions (functional requirements) and

required performance levels

[SOURCE: IEC 61508-4:2010, 3.5.11, modified, information from 3.5.12 included]

3.1.4

category

classification of the subsystem in respect of the resistance to faults and the subsequent behaviour in

the fault condition which is achieved by the structural arrangement of the parts, fault detection and/or

by their reliability

3.1.5

performance level

PL

discrete level used to specify the ability of safety-related parts of control systems to perform a safety

function under foreseeable conditions

Note 1 to entry: See 6.1.

3.1.6

required performance level

PL r

performance level required in order to achieve the required risk reduction for each safety function

Note 1 to entry: See 5.3 and Figure A.1.

3.1.7

safety integrity level

SIL

discrete level (one out of a possible four) for specifying the safety integrity requirements of safety

functions to be allocated to the safety-related systems, where safety integrity level 4 has the highest

level of safety integrity and safety integrity level 1 has the lowest

Note 1 to entry: In this document only SIL 1 to SIL 3 are considered.

[SOURCE: IEC 61508-4:2010, 3.5.8, modified – NOTES deleted and “allocated to safety-related systems”

added]

3.1.8

fault

state of a device characterized by the inability to perform a required function, excluding the inability

during preventive maintenance or other planned actions, Note 1 to entry: A fault is often the result of

a failure of the item itself, but can exist without prior failure.

Note 1 to entry: In this document “fault” means random fault or fault caused by a systematic failure.

[SOURCE: IEC 60050-192:2015, modified — NOTE 2 to entry amended.]

3.1.9

fault exclusion

exclusion of certain faults within a SRP/CS, if this can be justified due to their improbability and their

negligible contribution to the reliability of the SRP/CS

3.1.10

failure

termination of the ability of a device to perform a required function

Note 1 to entry: After a failure, the device has a fault.

Note 2 to entry: “Failure” is an event, as distinguished from “fault”, which is a state.

Note 3 to entry: Failures which only affect the availability of the process under control are outside of the scope of

this document.

[SOURCE: IEC 60050-192:2015, modified — NOTE 3 to entry had been amended.]

3.1.11

permanent fault

fault of an item that persists until an action of corrective maintenance is performed

[SOURCE: IEC 60050-192:2015]

3.1.12

dangerous failure

failure of an element and/or subsystem and/or system that plays a part in implementing the safety

function that:

a) prevents a safety function from operating when required (demand mode) or causes a safety

function to fail (continuous mode) such that the SRP/CS is put into a hazardous or potentially

hazardous state; or

b) decreases the probability that the safety function operates correctly when required

[SOURCE: IEC 61508 4:2010, 3.6.7, modified, "EUC" replaced by " SRP/CS"]

3.1.13

common cause failure

CCF

failure, that is the result of one or more events, causing concurrent failures of two or more separate channels in a multiple channel subsystem, leading to failure of a safety function

Note 1 to entry: Common cause failures are not identical with common mode failures (see ISO 12100:2010, 3.36).

[SOURCE: IEC 61508-4:2010, 3.6.10, NOTE 1 added]

3.1.14

systematic failure

failure related in a deterministic way to a certain cause, which can only be eliminated by a modification

of the design or of the manufacturing process, operational procedures, documentation or other relevant

factors

Note 1 to entry: Corrective maintenance without modification will usually not eliminate the failure cause.

Note 2 to entry: A systematic failure can be induced by simulating the failure cause.

Note 3 to entry: Examples of causes of systematic failures include human error in

— the safety requirements specification,

— the design, manufacture, installation, operation of the hardware, and

— the design, implementation, of the software.

[SOURCE: IEC 60050-192:2015]

3.1.15

muting

temporary automatic suspension of a safety function(s) by the SRP/CS

[SOURCE: IEC 61496-1:2012, 3.16]

3.1.16

manual reset

safety function within the SRP/CS used to restore manually one or more safety functions before re-

starting a machine

physical injury or damage to health

[SOURCE: ISO 12100:2010, 3.5]

3.1.18

hazard

potential source of harm

Note 1 to entry: A hazard can be qualified in order to define its origin (e.g. mechanical hazard, electrical hazard)

or the nature of the potential harm (e.g. electric shock hazard, cutting hazard, toxic hazard and fire hazard).

Note 2 to entry: The hazard envisaged in this definition:

— either is permanently present during the intended use of the machine (e.g. motion of hazardous moving

elements, electric arc during a welding phase, unhealthy posture, noise emission, high temperature);

— or can appear unexpectedly (e.g. explosion, crushing hazard as a consequence of an unintended/unexpected

start-up, ejection as a consequence of a breakage, fall as a consequence of acceleration/deceleration).

[SOURCE: ISO 12100:2010, 3.6, modified — NOTE 3 to entry has been deleted.]

3.1.19

hazardous situation

circumstance in which a person is exposed to at least one hazard

Note 1 to entry: The exposure can result in harm immediately or over a period of time.

[SOURCE: ISO 12100:2010, 3.10]

combination of the probability of occurrence of harm and the severity of that harm

[SOURCE: ISO 12100:2010, 3.12]

3.1.21

residual risk

risk remaining after risk reduction measures (protective measures) have been taken

Note 1 to entry: See Figure 3.

[SOURCE: ISO 12100:2010, 3.13, modified — Note 1 to entry has been modified.]

overall process comprising risk analysis and risk evaluation

[SOURCE: ISO 12100:2010, 3.17]

3.1.23

risk reduction measure

protective measure

action or means to eliminate hazards or reduce risks

EXAMPLE Inherently safe design; protective devices; personal protective equipment; information for use

and installation; organization of work; training; application of equipment; supervision.

[SOURCE: ISO Guide 51:2014, 3.13]

combination of the specification of the limits of the machine, hazard identification and risk estimation

[SOURCE: ISO 12100:2010, 3.15]

3.1.25

risk evaluation

judgement, on the basis of risk analysis, of whether risk reduction objectives have been achieved

[SOURCE: ISO 12100:2010, 3.16]

3.1.26

intended use of a machine

use of a machine in accordance with the information provided in the instructions for use

3.1.27

reasonably foreseeable misuse

use of a machine in a way not intended by the designer, but which can result from readily predictable

human behaviour

[SOURCE: ISO 12100:2010, 3.24]

3.1.28

safety function

function of the machine whose failure can result in an immediate increase of the risk(s)

Note 1 to entry: A safety function is a function to be implemented by a safety-related part of a control system,

which is needed to achieve or maintain a safe state for the machine, in respect of a specific hazardous event.

[SOURCE: ISO 12100:2010, 3.30]

part of a safety function whose failure results in a failure of the safety function

Note 1 to entry: A sub-function is a function to be implemented by a subsystem of the SRP/CS. See also

IEC 61800-5-2:2016.

EXAMPLE Sub-functions according to IEC 61800-5-2 are e.g. safe torque off (STO), safe stop 1 (SS1). See figure 6

diagnostic measure which detects a state and compares it to the expected value

Note 1 to entry: Monitoring is realised by following methods: plausibility check (direct. Indirect or cross

monitoring, see 3.1.24), cyclic test stimulus or cross monitoring.

3.1.31

cross monitoring

diagnostic measure which checks plausibility of redundant signals in both channels of a redundant subsystem

3.1.32

programmable electronic system

PE system

system for control, protection or monitoring based on one or more programmable electronic devices,

including all elements of the system such as power supplies, sensors and other input devices, data

highways and other communication paths, and actuators and other output devices

[SOURCE: IEC 61508-4:2010, 3.3.1]

3.1.33

mean time to dangerous failure

MTTF D

expectation of the mean time to dangerous failure

Note 1 to entry: In the case of items with an exponential distribution of operating times to dangerous failure (i.e.

a constant failure rate) the MTTF D is numerically equal to the reciprocal of the dangerous failure rate”.

[SOURCE: IEC 62061:2019, 3.2.34, modified — NOTE 1 to entry has been modified]

3.1.34

mean time between failures

MTBF

expected value of the operating time between consecutive failures

3.1.35

ratio of dangerous failures

RDF

fraction of the overall failure rate of an element that can result in a dangerous failure

3.1.36

diagnostic coverage

DC

measure of the effectiveness of diagnostics, which is determined as the ratio between the failure rate of

detected dangerous failures and the failure rate of total dangerous failures

Note 1 to entry: Diagnostic coverage can exist for the whole or parts of a safety-related system. For example,

diagnostic coverage could exist for sensors and/or logic system and/or power control elements.

3.1.37

mission time

![]()

period of time covering the intended use of an SRP/CS

3.1.38test rate

![]()

frequency of tests to detect faults in an SRP/CS, reciprocal value of diagnostic test interval

![]()

frequency of demands for a safety function to be performed by the SRP/CS

3.1.40

limited variability language

LVL

type of language that provides the capability to combine predefined, application specific, library

functions to implement the safety requirements specifications

Note 1 to entry: A LVL provides a close functional correspondence with the functions required to achieve the

application.

Note 2 to entry: Typical examples of LVL are given in IEC 61131-3. They include ladder diagram, function block

diagram and sequential function chart. Instruction lists and structured text are not considered to be LVL.

Note 3 to entry: Typical example of systems using LVL: Programmable Logic Controller (PLC) configured for

machine control

[SOURCE: IEC 62061, FDIS 2020, 3.2.62]

3.1.41

full variability language

FVL

type of language that provides the capability to implement a wide variety of functions and applications

Note 1 to entry: Typical example of systems using FVL are general-purpose computers.

Note 2 to entry: FVL is normally found in embedded software and is rarely used in application software.

Note 3 to entry: FVL examples include: Ada, C, Pascal, Instruction List, assembler languages, C++, Java, SQL.

[SOURCE: IEC 62061, FDIS 2020, 3.2.61]

3.1.42

safety-related application software

SRASW

software specific to the application and generally containing logic sequences, limits and expressions that control the appropriate inputs, outputs, calculations and decisions necessary to meet the SRP/CS requirements

3.1.43

safety-related embedded software

SRESW

firmware

software that is part of the system supplied by the manufacturer

Note 1 to entry: Embedded software is usually written in FVL.

[SOURCE: IEC 61511-1:2016, 3.2.76.2, modified – "and is not accessible for modification by the user of

the machinery" deleted]

3.1.44

high demand or continuous mode

mode of operation in which the frequency of demands on an SRP/CS to perform its safety function is

greater than one per year or the safety function retains the machine in a safe state as part of normal

operation

[SOURCE: IEC 61508-4:2010, 3.5.16]

3.1.45

low demand mode

mode of operation in which the frequency of demands on the SRP/CS to perform its safety function is

not greater than once per year

Note 1 to entry: Low demand mode is not addressed in this document, see Clause 1.

[SOURCE: IEC 61508-4:2010, 3.5.16, modified — NOTE amended]

3.1.46

subsystem

entity which results from a first-level decomposition of an SRP/CS and whose dangerous failure results

in a dangerous failure of a safety function

Note 1 to entry: The subsystem specification includes its role in the safety function and its interface with the

other subsystems of the SRP/CS.

Note 2 to entry: One subsystem can be part of one or several SRP/CS, e.g. the same combination of contactors can

be used to de-energise a motor in case of detection of a person in a danger zone and also in case of opening a safe

guard.

3.1.47

subsystem element

part of a subsystem comprising a single component or any group of components

Note 1 to entry: A subsystem element can comprise hardware or a combination of hardware and software. For

the purposes of this document, software-only components are not considered subsystem elements.

3.1.48

channel

element or group of elements that independently implement a safety function or a part of it

[SOURCE: IEC 61508-4:2010, 3.3.6]

3.1.49

well-tried safety principle

principles that have proved effective in the design or integration of safety-related control systems in

the past, to avoid or control critical faults or failures which can influence the performance of a safety

function

Note 1 to entry: Newly developed safety principles can only be considered as equivalent to well-tried if they are

verified using methods which demonstrate their suitability and reliability for safety-related applications.

Note 2 to entry: Well-tried safety principles are effective not only against random hardware failures, but also

against systematic failures which can creep into the product at some point in the course of the product life cycle,

e.g. faults arising during product design, integration, modification or deterioration.

Note 3 to entry: Table A.2(mechanical system), Table B.2(pneumetic system), Table C.2 (hydraulic) and Table D.2 of ISO 13849-2:2012 address well-tried safety

principles for different technologies.

3.1.50

well-tried component

component-successfully used in safety-related applications

Note 1 to entry: See 6.1.11 for requirements and ISO 13849-2 for a list of recognized well-tried components.

3.1.51

operating mode

mode of operation in a machine (e.g. automatic, manual, maintenance) to select predefined machine

functions and safety measures related to those functions

Note 1 to entry: For each specific operating mode, the relevant safety functions and/or risk reduction measures

are implemented.

Note 2 to entry: Operating mode is not a machine function itself. The functions (including safety functions)

summarized under an operating mode can only be used when that particular operating mode has been activated.

3.1.52

dynamic test

monitored diagnostic measure which at appropriate intervals executes a change of a signal for test

purposes

Note 1 to entry: The test fails if monitoring did not detect the change as expected.

Note 2 to entry: The use of test pulses is a common technology of dynamic testing and is widely used to detect

short circuits or interruptions in signal paths or malfunctions.

3.1.53

plausibility check

diagnostic measure which is monitoring that the state of an input (output) fits to the state of the system

or other inputs (outputs)

3.1.54

verification

confirmation, through the provision of objective evidence, that specified requirements have been

fulfilled

Note 1 to entry: The objective evidence needed for a verification can be the result of an inspection or of other

forms of determination such as performing alternative calculations or reviewing documents.

Note 2 to entry: The activities carried out for verification are sometimes called a qualification process.

Note 3 to entry: The word “verified” is used to designate the corresponding status.

[SOURCE: ISO 9000:2015, 3.8.12, .]

3.1.55

validation

confirmation by examination and provision of objective evidence that the particular requirements for a

specific intended use are fulfilled

Note 1 to entry: The objective evidence needed for a validation is the result of a test or other form of determination

such as performing alternative calculations or reviewing documents.

Note 2 to entry: The word “validated” is used to designate the corresponding status.

Note 3 to entry: The use conditions for validation can be real or simulated.

[SOURCE: IEC 61508-4:2010, 3.8.2]

3.1.56

skilled person

person with relevant training, education, and experience to enable him or her to perceive risks and to

avoid hazards associated with the relevant equipment

Note 1 to entry: Several years of practice in the relevant technical field can be taken into consideration in

assessment of professional training.

[SOURCE: ISO 14990-1:2016, 3.5.4, modified — “electricity” has been replaced by “the relevant

equipment”.]

3.1.57

Black box

device, system or object which can be viewed in terms of its inputs and outputs

3.1.58

grey box

device, system or object where some of the internal functions are known

Note 1 to entry: The third way for functional testing is “white box”, where all internal functions are known.

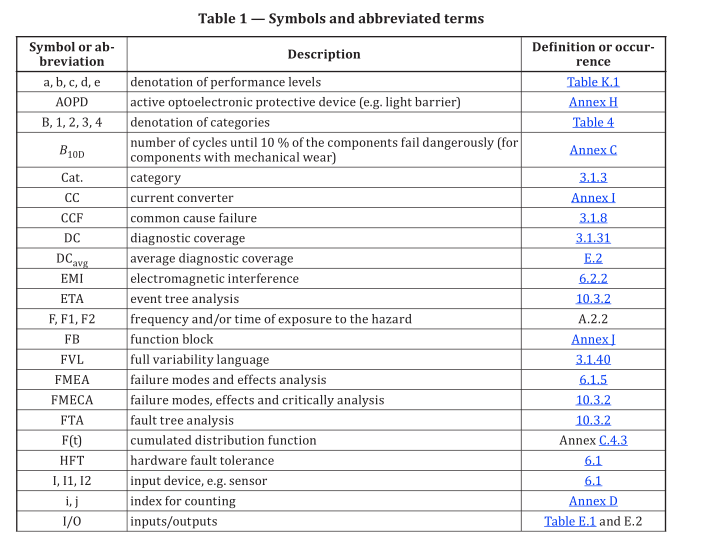

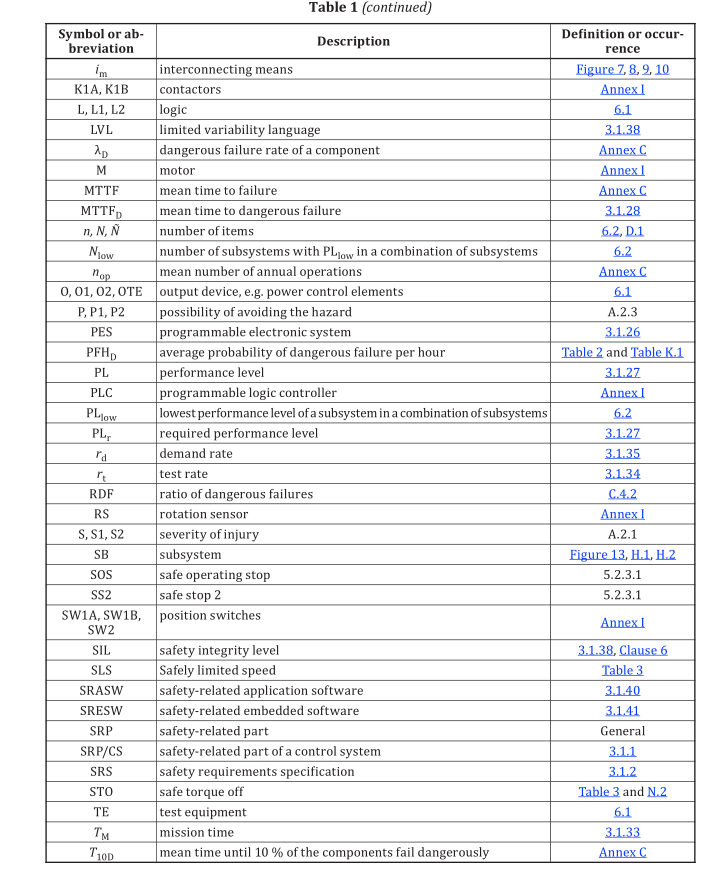

3.2 Symbols and abbreviated terms

Table 1 gives an overview on used abbreviations and terms.