EXAMPLE 1 Annex E of ISO 13849-2:2012 presents a complete worked example (which is very detailed) for

the validation of fault behaviour and diagnostic means on an automatic assembly machine.

EXAMPLE 2 ISO/TR 24119 describes a pragmatic step-by-step table-based methodology for evaluation of

diagnostic coverage for series connected interlocking devices.

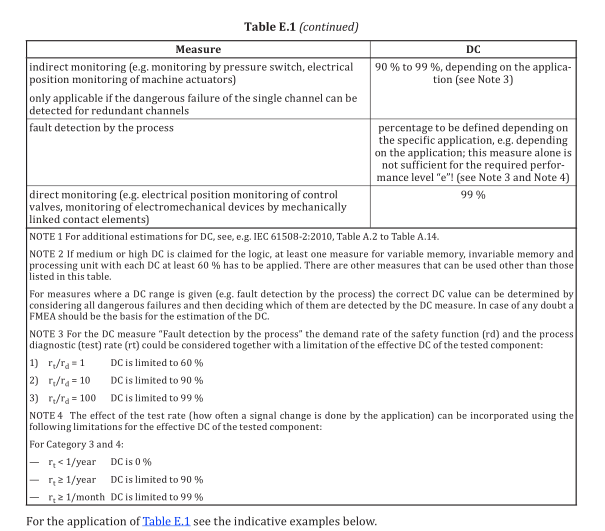

EXAMPLE 3 The DC measure “fault detection by the process” can only be applied if the safety-related

component is involved in the production process, e.g. a standard PLC or standard sensors are used for workpiece

processing and as part of one of two channels executing the safety function. The appropriate DC level depends

on the overlap of the commonly used resources (logic, inputs/outputs). For example, when all faults of a rotary

encoder on a printing machine lead to highly visible interruption of the printing process, the DC for this sensor

used to monitor a safely limited speed can be estimated as 90 % up to 99 %.

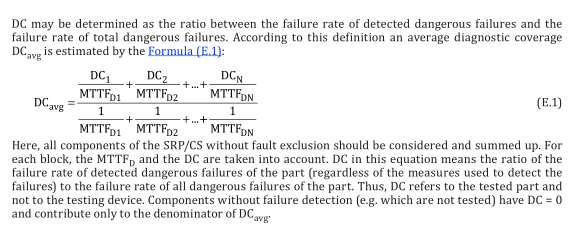

E.2 Estimation of the average diagnostic coverage

In many systems, several measures for fault detection might be used. These measures could check different parts of the SRP/CS and have different diagnostic coverage. For an estimation of the PL according to 6.1.8 and Figure 12 only one average DC for the whole SRP/CS performing the safety function is applicable.