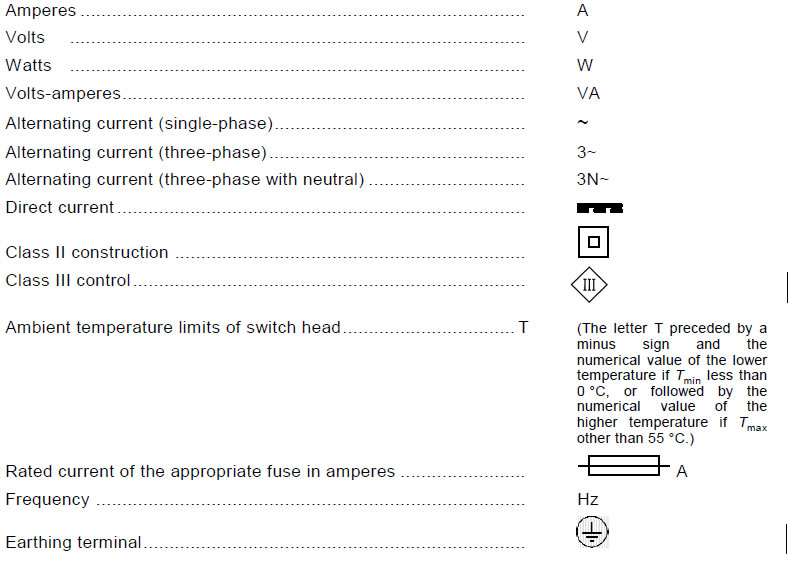

Table 7.2 Information |

Clause or subclause |

|

1 Manufacturer’s name or trade mark 2) |

7.2.6 |

C |

2 Unique type reference 1)2) |

2.11.1, 2.13.1, 7.2.6 |

C |

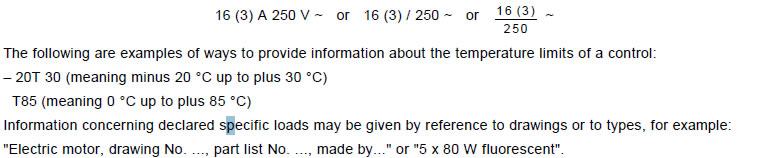

3 Rated voltage or rated voltage range in volts (V) |

2.1.2, 4.3.2 14.4, |

C |

4Nature of supply unless the control is for both a.c. and d.c., or unless therating is the same for a.c. and d.c. |

4.3.2, 6.1 |

C |

5 Frequency if other than for range 50 Hz to 60 Hz inclusive |

4.3.2 |

C |

6 Purpose of control |

2.2, 4.2.4,4.3.5, 6.3,17.16 |

D |

6a Construction of control and whether the control is electronic |

6.15, annex H, H.2.5.7 |

D |

7 The type of load controlled by each circuit 7) |

6.2, 14, 17, 23.1.1 |

C |

15 Degree of protection provided by enclosure 8) |

6.5.1, 6.5.2, 11.5 |

C |

17 Which of the terminals are suitable for the connection of external conductors,and if they are suitable for line or neutral conductors, or both |

6.6, 7.4.2, 7.4.3 |

C |

18 Which of the terminals for external conductors are for a wider range ofconductor sizes than those indicated in the table of 10.1.4. |

10.1 |

D |

19 For screwless terminals the method of connection and disconnection 9) |

10 |

D |

20 Details of any special conductors which are intended to be connected to the terminalsfor internal conductors |

10.2.1 |

D |

21 Maximum temperature of terminals for internal conductors and terminalsfor external conductors of incorporated and integrated controls, if higher than 85°C |

14 |

X |

22 Temperature limits of the switch head, if Tmin lower than 0 °C or Tmax otherthan 55 °C |

6.7, 14.5

14.7, 17.3 |

C |

23 Temperature limits of mounting surfaces (Ts) |

6.12.2, 14.1,17.3 |

C |

24 Classification of control according to protection against electric shock |

6.8 |

X |

25 For Class II controls, the symbol for Class II construction |

7.3 |

C |

26 Number of cycles of actuation (M) for each manual action |

6.10, 17.10,17.11 |

X |

27 Number of automatic cycles (A) for each automatic action |

6.11, 17.8,17.9 |

X |

28 Ageing period (Y) for controls with Type 1M or 2M action |

6.16, 17.6 |

X |

29 Type of disconnection or interruption provided by each circuit |

2.4.1, 2.4.2,2.4.3, 2.4.4,6.9 |

X |

30 PTI of materials used for insulation |

6.13,Table 20.3,note 2,

Table 20.4,note 1, 21.2.7 |

X |

31 Method of mounting control 5) |

11.6 |

D |

31a Method of providing earthing of control |

7.4.3, 9,9.1.1, 9.1.2 |

D |

32 Method of attachment for non-detachable cords 6) |

10.1, 11.7 |

D |

33 Intended transportation condition of control 20 |

16.1 |

X |

34 Details of any limitation of operating time 21) |

14, 17 |

D |

35 Period of electric stress across insulating parts |

6.14 |

X |

36 Limits of activating quantity for any sensing element over which micro disconnection is secure (see also H.7.2, item 36) |

11.3.2 |

X |

37 Minimum and/or maximum rates of change of actuating quantity, or minimum and/or maximum cycling rates for a sensing control 4) |

4.1.7, 15, 17 |

X |

38 Values of overshoot of activating quantity for sensing controls which are

necessary for correct action, or which can be used for test purposes |

17 |

X |

39 Type 1 or Type 2 action |

6.4 |

D |

40 Additional features of Type 1 or Type 2 actions |

6.4.3, 11.4 |

D |

41 Manufacturing deviation and condition of test appropriate to deviation |

2.11.1, 11.4.3,15 17.14 |

|

42 Drift |

2.11.2, 11.4.3,15, 16.2.4 |

X |

43 Reset characteristics for cut-out action 3) |

6.4 |

D |

44 If a control is either to be hand-held or is intended for a hand-held equipment |

21 |

X |

45 Any limitation to the number or distribution of flat push-on receptacles whichcan be fitted |

10.2.4.4 |

D |

46 Operating sequence for controls with more than one circuit, if significant |

11.4.3 |

D |

47 Extent of any sensing element |

2.8.1 |

D |

48 Operating value (or values) or operating time |

2.3.11, 2.3.12,6.4.3.10, 11,14, 15.6,17 |

D |

49 Control pollution degree |

6.5.3 |

D |

50 Control intended to be delivered exclusively to the equipment manufacturer |

7.2.1, 7.2.6 |

X |

51 Heat and fire resistance category Glow wire test temperatures |

21 21.2.1 – 21.2.4 |

X |

52 to 60 See annex H |

|

|

61 to 65 See annex J |

|

|

66 to 74 See annex H |

|

|

75 Rated impulse voltage |

2.1.12, 20.1 |

D |

76 Type of printed circuit board coating |

Annex P orAnnex Q |

X |

77 Temperature for the ball pressure test |

21.2.5 |

D |

78 Maximum declared torque on single bush mounting using thermoplastic

material |

Table 19.1, note 1 |

D |

79 Pollution degree in the micro-environment of the creep age or clearance if cleaner than that of the control, and how this is designed |

Table H.27.1 |

D |

80 Rated impulse voltage for the creep age or clearance if different from that of the control, and how this is ensured |

Table H.27.1 |

D |

81 The values designed for tolerances of distances for which the exclusion from fault mode "short" is claimed |

Table H.27.1 |

D |

82 to 84 See Annex J |

|

|

85 For Class III controls, the symbol for Class III construction |

7.4.6 |

C |

86 For SELV or PELV circuits, the ELV limits realized |

2.1.5, T.3.2 |

D |

87 Value of accessible voltage of SELV/PELV circuit, if different from 8.1.1,

product standard referred to for the application of the control, in which

standard(s) the accessible SELV/PELV level(s) is (are) given |

2.1.4, 6.8.4.1,6.8.4.2, 8.1.1 |

D |

88 See Annex U |

|

|

Items 8 to 14, inclusive, are void

NOTES

1) The unique type reference shall be such that, when it is quoted in full, the manufacturer of the control can

supply a replacement which will be fully interchangeable with the original electrically, mechanically,

dimensionally, and functionally.

It may comprise a series type reference with other marking, such as voltage rating or an ambient temperature

marking, which together provide a unique type reference.

2) Void

3) The manufacturer may declare a time before which, or a specific value of activating quantity above which,

manual reset shall not occur.

4) α1 = minimum rising rate

β1 = minimum falling rate

The rate of change (α1 and β1 ) of the activating quantity are those applicable to normal use.

α1 = maximum rising rate (for Type 2 actions only)

β1 = maximum falling rate (for Type 2 actions only)

For test purposes, α1 and β1 shall be as declared but not lower than the limit(s) indicated in the appropriate

Part 2s for Type 1 actions and/or Type 2 actions. The values α1 and β1 are for test purposes only, and may

alternatively be declared as a maximum cycling rate. The rates of change for the purpose of this standard

shall be expressed in the units as shown in the following table*:

| Activating quantity |

Unit for rate of change |

Pressure |

Pa/s |

Temperature |

K/h |

Position |

mm/s |

Illumination |

lux/s |

Velocity |

mm/s2 |

Liquid level |

mm/s |

Current |

A/s |

Humidity |

%/s |

Air flow |

m3/s2 |

" When using other activating quantities, the units shall be expressed in SI-units.

5) If, for independently mounted controls, it is necessary to take special precautions when installing or using

the control, these details shall be given in an instruction sheet accompanying the control.

Special precautions may be necessary, for example, for flush mounting independently mounted controls. In

order to ensure that, after building-in, the conditions necessary to meet the requirements of this standard are

achieved, the instruction sheet for such controls shall include clear information concerning:

– the dimensions of the space to be provided for the control;

– the dimensions and position of the means for supporting and fixing the control within this space;

– a minimum clearance between the various parts of the control and the surrounding parts of the fitment;

– the minimum dimensions of ventilating openings and their correct arrangements;

– the connection of the control to the supply and the interconnection of separate components, if any.

If the supply conductors of a control can come into contact with parts of a terminal block or a compartment

for fixed wiring, and these parts have, under conditions of normal use, a temperature exceeding that

specified in table 14.1, the instruction sheet shall also state that the control shall be connected by means of

conductors having the appropriate T rating (see note 1 of table 14.1).

6) In-line cord, free-standing and independently mounted controls, if fitted with non-detachable cords using

attachment methods Y or Z, shall have Documentation (D) containing the substance of one of the following

statements, whichever is appropriate:

– "The supply cord of this control cannot be replaced; if the cord is damaged, the control should be

discarded" (Z)

or

– "The supply cord of this control can be replaced only by the manufacturer or his accredited service agent" (Y).

7) For controls with more than one circuit, the current applicable to each circuit and to each terminal. If these

are different from each other, then it shall be made clear to which circuit or terminal the information applies.

For circuits for resistive and inductive loads, the rated current, or the rated load in VA, at power factors as

indicated in the appropriate table of 17.2.

8) The marking (C) requirement does not apply to controls or parts thereof classified as IP00, IP10, IP20, IP30

and IP40.

9) In Canada and the United States, marking (C) is required for the method of connection and disconnection of

screwless terminals for field wiring.

10) Void.

11) Void.

12) to 19) See annex H.

20) The method of packaging does not have to be declared.

21) For in-line cord, free-standing and independently mounted controls, this information shall be provided by

method C. |