5 Specification of safety functions .......................................................................................................................................... 17

5.1 Identification and general description of the safety function ....................................................................................................... 17

5.2 Safety requirements specification .............................................................................................................................................. 18

5.2.1 General requirements ........................................................................................................................ ....................................... 18

5.2.1.1 General

5.2.1.2 Necessary information to produce the safety requirements specification

5.2.1.3 Specification of all safety functions in the safety requirements specification

5.2.2 Requirements for specific safety functions ............................................................................................................................ 21

5.2.2.1 Safety-related stop function

5.2.2.2 Manual reset function

5.2.2.3 Restart function

5.2.2.4 Local control function

5.2.2.5 Muting function

5.2.2.6 Safety-related parameters

5.2.2.7 Fluctuations, loss and restoration of power sources

5.2.2.8 Requirements for operating mode selection

5.2.2.9 Safety function(s) for maintenance tasks

5.2.2.10 Motivation to defeat safety functions

5.2.2.11 Remote access

5.3 Determination of required performance level for each safety function ............................................................................... ... .. 25

5.4 Review of the safety requirements specification ................................................................................................................... ... 25

5.5 Decomposition of SRP/CS into subsystems . 5 Specification of safety functions

5.1 Identification and general description of the safety function

The objective of this subclause is to provide guidance on how to specify the requirements of each safety

function to be implemented by the SRP/CS.

Part of the risk reduction process is to determine the safety functions of the machine e.g. prevention of

unexpected start-up. A safety function may be implemented by one or more subsystems combined as an

SRP/CS, and several safety functions may share one or more subsystems [e.g. a logic unit, power control

element(s)].

Specification of the safety function can take place as described in ISO 12100, 6.2.11 and afterwards as a

part of the design specification for the SRP/CS under this document.

Clause 5 addresses the following steps:

1) General description of the safety function (linking hazards to safety functions)

2) Detailed description of the safety requirements (see 5.2);

3) Determination of the PL r for each safety function how reliable the safety function needs to be –

see 5.3;

4) Review of the safety requirements specification (see 5.4).

A safety function shall have a general description to define how the SRP/CS contributes to risk

reduction. The description shall be linked to hazards identified in the risk assessment and shall state

how the function operates to achieve the required safety. The process for specifying safety functions

requires detailed information from the risk assessment performed in accordance with ISO 12100:2010.

5.2 Safety requirements specification

5.2.1 General requirements

5.2.1.1 General

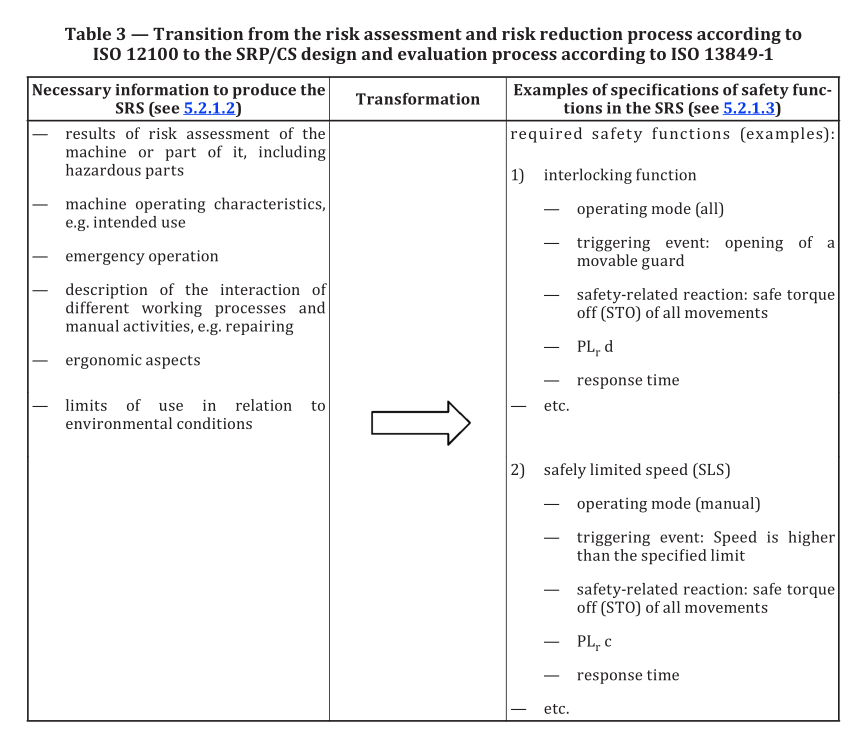

The safety requirements specification shall document details of each safety function to be performed.

The safety requirements specification is intended to prevent mistakes at the transition from the

risk assessment and risk reduction process according to ISO 12100:2010 to the SRP/CS design and

evaluation process according to this document, especially if these two processes are performed by

different persons or organizations (see Table 3).

5.2.1.2 Necessary information to produce the safety requirements specification

NOTE The following information is used for technical documentation. For information for users see 13.3.

The following information shall be available to the designer of the safety-related control system to

develop the safety requirements specifications where relevant:

a) Results of the risk assessment of the machine or part of it for each specific hazard where the

associated risk reduction measure(s) rely on a safety-related control system to perform a safety

function;

b) machine operating characteristics, including:

1) intended use of the machine

2) reasonably foreseeable misuse,

3) effect of overlapping hazards

4) operating modes (e.g. local mode, automatic mode, modes related to a zone or part of the

machine),

5) the mode(s) of operation during which the safety function is to be active

6) cycle time, and

7) response time until a safe state is achieved (see also ISO 13855:2010, 5.1);

NOTE 1 The response time of the control system is part of the overall response time of the machine.

The required overall response time of the machine can influence the design of the safety-related part,

e.g. the need to provide a braking system.

NOTE 2 Operational functions (e.g. starting, normal stopping) can also be safety functions, but this

can be ascertained only after a complete risk assessment on the machinery has been carried out.

c) emergency operation (IEC 60204-1:2016, Annex E);

d) description of the interaction of different working processes and manual activities (e.g. repairing,

setting, cleaning, trouble shooting, modes of operation with the safeguards suspended);

e) ergonomic aspects to minimize incorrect operation or defeating;

f) limits of use in relation to environmental conditions;

g) effect of overlapping hazards (see Annex A.3).

5.2.1.3 Specification of all safety functions in the safety requirements specification

The SRS shall have the following information for each safety function in relation to the specific

application:

a) the brief description / title of the safety function to have a clear reference;

b) the event that triggers the safety function;

c) the reaction to be initiated by the safety function output(s) to reach the intended safe state;

EXAMPLE 1 Stop hazardous movements.

d) the required performance level PL r for each safety function (see 5.3);

e) the response time for the machine to achieve a safe state after the demand is made upon the safety

function e.g., the overall system stopping performance (reaction time plus stopping time) according

to ISO 13855:2010;

f) the operating mode(s) during which the safety function is to be active;

g) interfaces of the safety functions;

h) if needed, in case of a fault detection in a functional channel, procedures to bring the machine to a

safe state including how the safe state is maintained until the fault is repaired;

EXAMPLE 2 If there is a fault in a functional channel and a stop category 1 is not possible, then a fault

reaction can be initiated by using stop category 0. For stop categories, see IEC 60204-1.

i) the behaviour of the machine on the loss of power (see 5.2.3.7);

NOTE It can be necessary to hold a vertical axis in position to prevent a fall due to gravity forces.

Where external forces can have an impact on functional safety, for instance on those gravity loaded

axes, a reinforcement (e.g. for power elements) can be necessary because of systematic requirements. An

appropriate design solution can be the integration of a non-return valve on cylinders or supplementary

mechanical brakes. This can also require the design of two separate safety functions: One with power

available and another without power available.

j) the demand rate of the safety function and/or the frequency of operation of the SRP/CS;

k) the priority of the safety functions that can be simultaneously active and that can cause conflicting

action;

EXAMPLE 3 An emergency stop function has priority over all other functions.

EXAMPLE 4 The safely limited speed (SLS) function can be a precondition of a "hold to run" safety

function.

l) safety-requirements of type C standards for the design of an SRP/CS or subsystem (e.g.

ISO 23125:2015, ISO 16090-1:2017).

The above is a non-exhaustive list of details for safety functions that can be provided by the SRP/CS.

See also Annex M for typical safety functions and their characteristics and safety-related parameters.

5.2.2 Requirements for specific safety functions

5.2.2.1 Safety-related stop function

A safety-related stop function (e.g. initiated by a safeguard) shall as soon as necessary after actuation,

put the machine in a safe state. Such a safety-related stop-function shall have priority over all relevant

starts and non-safety-related stops. When a group of machines is working together in a coordinated

manner, provision shall be made for signalling the supervisory control and/or the other machines that

such a stop condition exists.

As a result of the risk assessment, safety-related stop functions can be realised according to the stop

categories in IEC 60204-1:2016, 9.2.2.

NOTE IEC 61800-5-2:2016 provides information about safety-related power drive system including

descriptions of safe-torque off (STO), safe stop 1 (SS1), safe stop 2 (SS2), safe operating stop (SOS).

After a stop command has been initiated by a safety function, the stop condition shall be maintained

until safe conditions for restarting exist. See also Table M.1 in Annex M.

5.2.2.2 Manual reset function

The re-establishment of the safety function by resetting of the safeguard cancels the stop command. If

indicated by the risk assessment, this cancellation of the stop command shall be confirmed by a manual,

separate and intended action (manual reset).

The manual reset function shall:

— be provided through a separate and manually operated device that is separate from start command,

— only be achieved if all affected safety functions and safeguards are operational,

— not initiate a hazardous situation by itself,

— be initiated by intended action,

— enable the control system to accept a separate start command, and

— be accepted by monitored signal change, in order to avoid foreseeable misuse.

When the function “manual reset” is required to be a safety function (e.g., prevention of unexpected

start), the required performance level shall be determined. The PL of the manual reset function can be

different from the PL r of the associated safety function.

NOTE It is not always necessary that the manual reset function has the same PL r as the associated safety

function.

The reset actuator shall be located outside the hazard zone and in a position from which there is

sufficient visibility to ensure that no person is inside the hazard zone. It shall not be possible to activate

the reset function from inside the hazard zone.

Where the visibility of the hazard zone is not sufficient, specific reset sequence or monitoring of the

area that is not visible, shall be provided.

EXAMPLE One solution is the use of a sequenced resetting. The reset function is initiated within the hazard

zone by the first actuator in combination with a second reset actuator located outside the hazard zone (near

the safeguard). This reset procedure can be realized within a limited time before the control system accepts a

separate start command. Monitoring of the area can be done by e.g. use of presence sensing devices that detect

persons in hazard zones not visible from the reset position.

See also Table M.1.

5.2.2.3 Restart function

A restart shall take place automatically only if the safe condition is guaranteed. In particular, for

interlocking guards with a start function, ISO 12100:2010, 6.3.3.2.5 applies.

EXAMPLE In automatic machine operations, sensor feedback signals to the control system are often used to

control the process flow. If a work piece has come out of position, the process flow is stopped. If the monitoring

of the interlocked safeguard does not have a higher priority to the automatic process control, there could be

a danger of unexpected restarting of the machine while the operator readjusts the workpiece. Therefore, the

automatic restart ought not to be allowed until the safeguard is closed again and the operator has left the hazard

zone. The contribution of the prevention of unexpected start-up (see ISO 14118:2017) provided by the control

system is dependent on the result of the risk assessment.

See also Table M.1

5.2.2.4 Local control function

When a machine is controlled locally, e.g. by a portable control station that can be a portable device or

pendant, the following requirements shall apply:

— the means for granting local control shall be situated outside the hazard zone;

— it shall only be possible to initiate command by a local control station in a zone defined by the risk

assessment in order to avoid hazardous situations;

— switching between local and a different another control shall not create a hazardous situation;

— initiation of commands from multiple control stations (local or remote) shall not lead to a hazardous

situation. It can be necessary to preclude use of other control stations when a local control station

is selected or when certain commands are initiated.

See also Table M.1.

5.2.2.5 Muting function

Muting is a temporary automatic suspension of a safety function by the machine safety-related control

system. It can be used to allow access by persons or by materials:

— during a non-hazardous portion of the machine cycle, or

— when safety is maintained by other means.

The muting function shall be initiated and terminated automatically. This shall be achieved by the use

of appropriately selected and placed sensors or by signals from the machine control system. Incorrect

signals, sequence, or timing of the muting sensors or signals shall not allow a mute condition.

The part or parts of the control system that performs the muting function shall have an appropriate

safety-related performance (SIL according to IEC 62061 or PL according to this document) and shall

not reduce the safety-related performance of the protective function below that required for the

application.

At the end of muting, all affected safety functions shall be reinstated and active.

The implementation of muting shall meet the requirements of IEC 62046:2018. See also Table M.1.

5.2.2.6 Safety-related parameters

When safety-related parameters, e.g. position, speed, temperature, time, torque or pressure, deviate

from present limits the safety-related control system shall initiate appropriate measures.

If errors in manual inputting of safety-related data in programmable or configurable electronic systems

can lead to a hazardous situation, then a data checking system within the safety-related control system

should be provided, e.g. check of limits, format and/or logic input values. For additional requirements,

see 7.5 and see also Table M.2.

Annex O provides information on safety-related values of components or parts of control systems.

5.2.2.7 Fluctuations, loss and restoration of power sources

When fluctuations in energy levels outside the design operating range occur, including loss of energy

supply, the SRP/CS shall continue to provide or initiate output signal(s) which will enable other parts of

the machine system to maintain a safe state. See also Table M.2.

5.2.2.8 Requirements for operating mode selection

Selection of operating mode is a safety function when the selection enables or disables safety function(s).

The following is required:

a) only one operating mode shall be active at a time; each selected operating mode shall be clearly

identifiable or indicated;

NOTE It is sufficient that a mode can be identified or indicated in the overall safety function.

b) mode selection by itself shall not initiate machine operation. A separate actuation of the start

control shall be required.

c) when changing from one operating mode to another, safety functions and/or risk reduction

measures necessary for the selected operating mode shall be activated without any loss of the

intended risk reduction during the transition.

The operating mode selection function shall be implemented as a safety function, if it is required by

the risk assessment, by considering the systematic requirements a) to c). The means of selecting the

operating mode shall not degrade the PL of the safety functions active in that mode.

5.2.2.9 Safety function(s) for maintenance tasks

The design of the machine shall take into account maintenance tasks on the machine and provide safety

functions for these tasks. The results of the risk assessment for each relevant safety function shall be

considered in the specification of the SRP/CS.

NOTE 1 Maintenance tasks can include, but are not limited to:

— setting;

— teaching/programming;

— process/tool changeover;

— cleaning and housekeeping;

— sanitizing;

— planned or unplanned preventive or corrective maintenance;

— troubleshooting/fault finding;

— fault diagnosis..

Some maintenance task require a full isolation of the machine from all power sources and therefore

do not rely on the SRP/CS. For maintenance tasks that require power and/or machine movements

while maintenance personnel are inside the hazard zone, and where manual suspension or override

of specific safety functions is needed it shall only be allowed by providing alternative and appropriate

safety functions (e.g. enabling device safety function with a speed limiting safety function).

EXAMPLE Teaching/ programming, troubleshooting, process fine-tuning are tasks requiring power and

machine movement.

The following safety functions are examples of what is often provided for maintenance tasks:

a) hold-to-run;

b) enabling control;

c) monitoring or limiting of speed, torque, power, position, location, temperature, level, etc.;

d) prevention of unexpected start-up;

e) isolation and energy dissipation;

f) mechanical restraint or containment.

NOTE 2 See Annex M for additional information.

The motivation to defeat or circumvent risk reduction measures provided by the SRP/CS during

maintenance of the machine shall be considered when specifying, designing and selecting the SRP/CS

(see 5.2.2.10).

The SRP/CS shall include consideration that additional personnel other than the intended operator(s)

perform a task, e.g.:

— an operator performs reset and restart functions while maintenance personnel are inside the

hazard zone;

— risk reduction measures intended to protect an individual are inappropriately used for multiple

personnel;

In maintenance mode, the design of the SRP/CS shall prevent a remote access (see 5.2.2.11) to the

machine control system without appropriate notification or indication to persons that are at or near the

machine.

5.2.2.10 Motivation to defeat safety functions

The motivation to defeat or circumvent a safety function depends on the process, the intended use

of the machine (or part of the machine) and the design details of the risk reduction measure(s). The

motivation to defeat a safety function shall be minimized in the design of the SRP/CS.

NOTE 1 Providing means to perform tasks easily whilst protecting operators can lessen the motivation to

defeat or circumvent safety function(s) and/or safeguard(s).

NOTE 2 ISO 14119 gives a method and shows examples how to minimize possibilities to defeat an interlocking

device.

NOTE 3 Safety research has shown that many injuries occur due to defeat of safety function and/or safeguards.

See Bibliography for more information.

EXAMPLE Motivations to defeat or circumvent a risk reduction measure (including safety function(s)) can

be that:

— the risk reduction measure prevents the task from being performed; there is a need to perform a task that

was not identified and assessed for hazards and risks;

— the risk reduction measure slows down production or interferes with any other activities or preferences of

the user;

— the risk reduction measure is difficult to use;

— the risk reduction measure and/or its associated hazard is not recognized as such by personnel;

— the risk reduction measure is not accepted as suitable, necessary or appropriate for its function.

The use and access to programmable systems introduces an additional possibility to defeat or

circumvent safety functions if not properly applied or supervised.

5.2.2.11 Remote access

When a machine is capable of remote access, the SRP/CS shall remain operational. Alternative risk

reduction measures can be used when provided in the information of use.

The design of the SRP/CS shall not allow remote access of a machine without specific measures to

prevent dangerous situations that can arise due to the presence of persons being inside or near to the

machine.

NOTE A remote start that is unexpected to persons working at the machine can lead to injury.

5.3 Determination of required performance level for each safety function

For each selected safety function a required performance level (PL r ) shall be determined and

documented. The determination of the PL r shall be based on the result of the risk assessment of the

machine or part of it and shall correlate to the needed risk reduction (see Figure 3). Annex A provides

guidance for the determination of the PL r for the safety function. Overlapping hazards if relevant also

need to be considered when defining the safety functions. See A.3 for further guidance.

NOTE 1 Other methods like the method presented in IEC 62061 can be used instead.

NOTE 2 Type-C standard typically provide information on PL r .

As the methodology for determining the required performance level includes subjective estimations,

some variability is acceptable in the practical application of particular cases. This variability shall be

taken into account when defining PL r .

NOTE 3 The PL r for a safety function determines the reliability of the control system to execute the safety

function and to achieve the intended risk reduction. The PL r is determined using several factors of risk. See also

Annex A.

5.4 Review of the safety requirements specification

The safety requirements specification shall be verified against the risk assessment before starting

the design, since every other activity is based on these requirements. The review shall ensure that all

safety functions are specified to achieve the intended risk reduction at the machine. See also 10.4 for

the validation of the SRS.

NOTE Depending on the specific safety functions it can be useful to have independence between who

prepares the SRS and who reviews it.

5.5 Decomposition of SRP/CS into subsystems

The safety functions shall be decomposed into sub-functions that are allocated to subsystems. The

description of each sub-function shall include

— the safety requirements for the sub-function (functional and integrity), and

— inputs and outputs of each sub-function.

An SRP/CS can comprise:

— one or several previously validated subsystem(s);

— one or several subsystem(s) based on subsystem element(s);

— a combination of both alternatives above.

By definition, a dangerous failure of any subsystem results in the loss of the whole safety function.

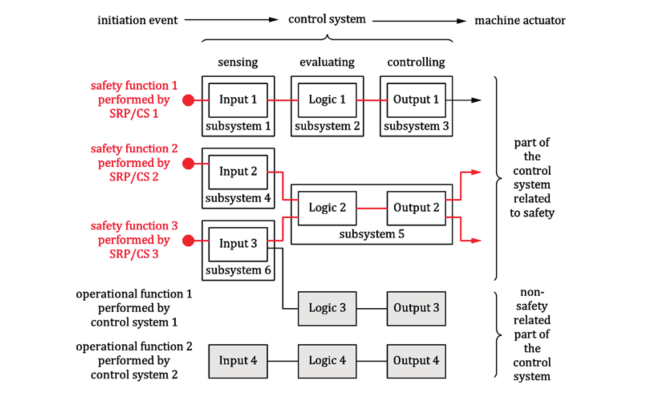

EXAMPLE Figure 6 provides an example of decomposition starting with a detection and evaluation of an

‘initiating event’ (e.g. manual actuation of a push button, opening of guard, interruption of beam of AOPD) and is

ending with an output causing a safe reaction of a ‘machine actuator’ (e.g. motor, cylinder)

NOTE 1 Safety function 1 is decomposed into sub-function 1, sub-function 2 and sub-function 3. Sub-function

1 is performed by subsystem 1.

NOTE 2 Safety function 2 is decomposed into sub-function 4 and sub-function 5. Sub-function 4 is performed

by subsystem 4.

NOTE 3 Safety function 3 is decomposed into sub-function 6 and sub-function 5. Sub-function 6 is performed

by subsystem 6.

Figure 6 — Example of decomposition of safety functions and their allocation to subsystems

Figure 6 shows a diagrammatic presentation of subsystems combined as SRP/CS(s) for:

— initiation event (e.g. opening of a guard, interruption of beam of AOPD);

— input (e.g. limit switch, sensor, AOPD) (subsystems 1, 4 and 6),

— logic/processing (subsystems 2 and 5),

— output/power control elements (e.g. valve, contactor, current converter, brakes) (subsystems 3 and

5),

— machine actuator (e. g. motor, cylinder),

— interconnecting means (e.g. electrical, optical).

NOTE 1 The decomposition of an SRP/CS into subsystems represented in Figure 6 is typical but the whole

SRP/CS may be also realized by a single subsystem or more than three subsystems.

NOTE 2 An SRP/CS can be implemented by one single subsystem having a sensor, logic and power control

elements. Example for an SRP/CS implementation with a single subsystem is an “Intelligent” sensor unit (e.g. light

curtain, laser scanner) with integrated output switching device (e.g. relay to switch-off a dangerous movement).

NOTE 3 It is also possible that one subsystem or SRP/CS implements safety functions and standard control

functions. The designer can use any of the technologies available, singly or in combination. SRP/CS can also

provide an operational function (e.g. an AOPD as a means of cycle initiation).

NOTE 4 The designer of a previously validated subsystem can be a system integrator, machine manufacturer

or a component manufacturer.

The manufacturer of a previously validated subsystem shall provide the relevant information according to 13.2.